What are Tilt Sensors?

What is an electrolytic tilt sensor?

Catalog

| |

Ⅰ Introduction

With the continuous development of production and science, angle measurement is more and more widely used in various fields such as industrial scientific research, and the market's demand for sensors is also increasing. From the point of view of the definition alone, the tilt sensor is used to measure the change in the tilt angle relative to the horizontal plane.

To calculate changes in the horizontal angle of the device, tilt sensors are also used. It has become an invaluable and important measuring tool in the detection fields such as bridge erection, railway laying, structural engineering, oil drilling, aviation and navigation, factory robotics, intelligent platforms, and mechanical manufacturing. For calculating small angles, the electronic level is a very precise detection instrument. Relative to the horizontal position, the reciprocal parallelism, and the perpendicularity of the two parts, the inclination of the measured plane can be measured.

Ⅱ Basic Principle

A significant aspect of geometrical calculation is angle measurement. The variety of angles is wide. In the horizontal axis, the plane angle can be broken into the horizontal angle and the vertical angle in the vertical plane. The synthesis of the horizontal angle and the vertical angle is the spatial angle.

The scientific cornerstone is the second law of Newton: according to simple physical concepts, speed can not be determined within a device, but its acceleration can be measured. The linear velocity determined by integration if we know the initial velocity, and the linear displacement can be calculated. It's basically an acceleration sensor using the inertia principle. In the lateral and vertical directions, if the tilt sensor is stationary, then only gravity acceleration operates on it. The angle between the longitudinal gravity axis and the critical acceleration sensor axis is called the tilt angle. The tilt sensor is a static or quasi-static calculation in the general sense of the term. When the external acceleration exists, the external acceleration is used in the acceleration determined by the acceleration chip, so the angle determined is not precise. The common practice now, however, is to raise the Gyro chip mems and use the priority Kalman filter algorithm. Acceleration has 3 axes and the gyroscope has 3 axes. All the elements here are often referred to as 6-axis or VG (vertical gyro).

Ⅲ Types

For measuring the horizontal distance of the device and the height of objects, tilt sensors are also used. From the working principle, they can be divided into three types of tilt sensors: solid pendulum, liquid pendulum, and gas pendulum. These three types of inclination sensors all use the earth's gravity. The function is to convert the attitude angle of the sensor-sensitive device to the earth, that is, the physical quantity of the included angle with the earth's gravity into an analog signal or a pulse signal.

1 Solid pendulum tilt sensor

Schematic diagram of the solid pendulum

It is composed of a pendulum, a cycloid, and a bracket, as seen in the figure. Gravity G and the pendulum pushing power T are influenced by the pendulum.

F =G sinθ=mg sinθ

The θ in the formula is the angle between the cycloid and the vertical. When measuring in a small angle range, F and θ can be considered to have a linear relationship. The strain-type tilt sensor is based on this principle.

2 Liquid pendulum tilt sensor

Schematic diagram of the liquid pendulum

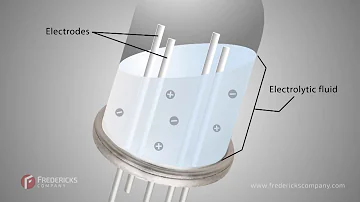

The structure principle of the liquid pendulum is that there is a conductive liquid in the glass shell, and there are three platinum electrodes connected to the outside. The three electrodes are parallel to each other and have equal spacing, as shown in the figure.

When the shell is at a horizontal level, the electrode is inserted into the conductive liquid to the same depth. If an alternating voltage of equal amplitude is applied between two electrodes, an ionic current will be formed between the electrodes. The liquid between the two electrodes is equivalent to two resistors RI and RIII.

If the liquid is horizontal, then RI=RIII.

diagram of the liquid pendulum when the angle is α

When the glass shell is inclined, the conductive liquid between the electrodes is not equal, and the depth of the three electrodes immersed in the liquid also changes, but the immersion depth of the middle electrode remains basically unchanged. As shown in the figure, if the immersion depth of the left electrode is small, the conductive fluid will decrease, the number of conductive ions will decrease, and the resistance RI will increase, while the opposite pole will increase the conductive fluid and the number of conductive ions will increase, and the resistance RIII will decrease, ie RI>RIII. Conversely, if the tilt direction is opposite, RI<RIII.

3 Gas pendulum tilt sensor

The "gas pendulum" type inertial element is composed of a closed cavity, gas, and hot wire. When the plane of the cavity is inclined relative to the horizontal plane or the cavity is subjected to acceleration, the resistance of the hot wire changes. The change in resistance of the hot wire is a function of the angle q or the acceleration, so it also has a pendulum effect. The change in resistance of the hot wire is caused by the energy exchange between the gas and the hot wire.

The sensitive mechanism of the "gas pendulum" type inertial device is based on the energy transfer in a closed cavity. There are gas and hot wires in the closed cavity, and the hot wires are the only heat source. When the device is energized, it heats the gas. Convection is the main form of heat exchange energy.

Ⅳ Characteristics

The tilt sensor integrates the MCU, MEMS accelerometer, analog-to-digital conversion circuit, and communication unit on a very small circuit board. It can directly output tilt data such as angle so that people can use it more conveniently.

High-precision single-axis tilt angle sensor

The single-axis tilt angle sensor based on capacitive 3D-MEMS technology can show its excellent reliability in all temperature areas, extraordinary stability, and unprecedented high precision. Tilt angle sensors are designed, produced, and tested according to the reliability and stability requirements of the automotive industry. The tilt angle sensor has significant load capacity and very good impact durability, without the need for additional other components. The tilt sensor is a member of the analog acceleration sensor product and is fully compatible with the acceleration sensor.

Dual-axis tilt sensor

The tilt sensor can adjust the output frequency, the built-in zero adjustments, and the zero adjustment button can be customized according to the requirements, so as to realize the function of setting zero at a certain angle. This is very useful for situations where you want to measure relative inclination, and you can return to the zero position after use. The tilt sensor is used on this kind of occasion. As long as the sensor is fixed on a certain plane, the zero button is used to realize the reset function before measurement. The data read by the sensor after that is the relative tilt angle with respect to the plane.

Filtering function

When the output is required to be relatively stable, it is recommended to use a relatively gentle output, so that the output value tends to be flat, and the change is not too drastic. If a very timely output is required, such as in the measurement of higher frequency vibration, the high-frequency output can be used, but the output will be unstable due to the very short response time. At the same time, the internal filtering function can be used to achieve the goal of measuring the inclination angle in vibration situations.

Tilt measurement

The principle of tilt measurement is that express the rotation of a coordinate system in the form of Euler angles with the cooperation of two axes, which can realize the measurement of 360-degree inclination. In some occasions where full-scale tilt angle measurement is required, it is ideal to choose a 360-degree product.

Ⅴ Applications

1. Applied to the agricultural dump truck

Because dump trucks usually work in an environment with a certain slope, a large number of dump truck manufacturers install a dual-axis tilt sensor on the truck. A special display instrument is designed to display the angle measured by the sensor for the drivers, providing them with reliable reference driving data. Not only that, when the dump truck is driving on a relatively horizontal road, the inclination sensor can also measure the current inclination angle during driving, providing accurate reference data for minor changes in the body structure.

2. Applied to tower crane

In the tower crane anti-tipping monitor, the main part is the tilt sensor. The function of the tilt sensor is to measure the tilt angle of the tower in real-time. Because the tilt angle at the top of the tower doesn’t change much, the sampling frequency of the tilt sensor should be within the range of 0.5-10 Hz, and the measurement accuracy should be higher than 0.05 degrees. At the same time, it is necessary to filter out the noise caused by the vibration on the top of the tower to ensure reliable communication and accurate judgment.

3. Applied to plate conveyor

During the installation process of the plate conveyor, the tilt sensor can be installed on the top of the conveyor, and the current inclination angle of the conveyor can be directly measured, which greatly simplifies the installation process. The installation speed and work efficiency of the plate conveyor are greatly improved by using the inclination sensor instead of the previous installation by experience.

4. Applied to CNC machine tools

How to ensure the geometric accuracy of machining in the process of machining parts of CNC machine tools? This depends on the geometric accuracy of the CNC machine tool. The geometric accuracy of the CNC machine tool comprehensively reflects the geometric error of the key parts of the machine tool after assembly, and the tilt sensor is the best choice for controlling the geometric accuracy of the CNC machine tool.

The geometric accuracy inspection of CNC machine tools includes the flatness of the work surface, the mutual perpendicularity of the movement of each coordinate direction, the parallelism of the work surface when moving in the X coordinate direction, and the parallelism of the work clothes surface when moving in the Y coordinate direction. Levels are used in the inspection items, but with the development of technology and the improvement of sensor technology, in the geometric accuracy inspection of CNC machine tools, the inclination sensor is gradually used to check the flatness and perpendicularity. The tilt sensor can not only know whether the plane is Horizontal or vertical but also quantitatively know the level or vertical to what degree, it is better to check the geometric accuracy of the machine tool.

What is a tilt sensor used for?

Tilt sensors allow you to detect orientation or inclination. They are small, inexpensive, low-power and easy-to-use. If used properly, they will not wear out. Their simplicitiy makes them popular for toys, gadgets and appliances.

What is a tilt sensor in a car?

A Tilt sensor is an optional security sensor that triggers the alarm whenever your vehicle gets jacked up, for stealing wheels or towing.

How does inclination sensor work?

Inclinometers, also called tilt sensor, clinometers or slope sensors, are designed to measure the angle of an object with respect to the force of gravity. These tilt or level meters determine the pitch and/or roll angle and output these values via the appropriate electrical interface.

How do you test a tilt sensor?

Put your multimeter into continuity-test mode and touch the probes to the two leads. Then tilt to determine the angle at which the switch opens and closes. When pointing down, the switch is Open Loop (no continuity).

How do you use a tilt sensor?

To connect a Tilt sensor with the Arduino, it requires 5v dc input to operate. That 5v is supplied using Arduino UNO and the output of Tilt sensor is taken at PIN 4 of the Arduino. LED is connected with the PIN 2 of the Arduino UNO with 220-ohm resistor to limit the current to a safe value.

The Key Role of Electronic Components in IoT DevicesUTMEL01 September 20234994

The Key Role of Electronic Components in IoT DevicesUTMEL01 September 20234994The article discusses the pivotal role of electronic components in Internet of Things (IoT) devices. IoT devices work by capturing real-world data using sensors, processing it through a microcontroller, and then sending it to the cloud for further analysis.

Read More How to Identify the Perfect Proximity Sensor for Your ApplicationUTMEL19 July 2025901

How to Identify the Perfect Proximity Sensor for Your ApplicationUTMEL19 July 2025901Find the best proximity sensors for your project by evaluating material, sensing range, environment, and system needs to ensure optimal performance and reliability.

Read More Trusted Vibration Sensors for Homeowners and Industry ProfessionalsUTMEL17 July 2025606

Trusted Vibration Sensors for Homeowners and Industry ProfessionalsUTMEL17 July 2025606Compare top vibration sensors for home and industrial use. Find trusted options for security, predictive maintenance, and equipment protection.

Read More Wiring and Mounting Photoelectric Sensors in 2025UTMEL15 July 2025808

Wiring and Mounting Photoelectric Sensors in 2025UTMEL15 July 2025808Wire and mount photoelectric sensors in 2025 with step-by-step safety, wiring, and alignment tips for reliable installation and optimal sensor performance.

Read More Essential Tips for Picking the Best Gas SensorUTMEL15 July 20251909

Essential Tips for Picking the Best Gas SensorUTMEL15 July 20251909Find out how to select gas sensors by matching target gases, environment, and compliance needs for reliable and accurate gas detection in any setting.

Read More

Subscribe to Utmel !

![T0054470699]() T0054470699

T0054470699Apex Tool Group

![T0054451999]() T0054451999

T0054451999Apex Tool Group

![T0054449499]() T0054449499

T0054449499Apex Tool Group

![ETB-5]() ETB-5

ETB-5Apex Tool Group

![UMMYA-0750-1500-1]() UMMYA-0750-1500-1

UMMYA-0750-1500-1Omron Automation and Safety

![38-855]() 38-855

38-855Apex Tool Group

![3872-3]() 3872-3

3872-3API Delevan

![EBM60TZ220]() EBM60TZ220

EBM60TZ220Menda

![EPM80CP303]() EPM80CP303

EPM80CP303Menda

![50712]() 50712

50712Elesa USA Corporation