Basic Introduction to Color Sensor

How the Color Sensor Works

Catalog

| |

Ⅰ Introduction

The principle of the color sensor is to obtain color data by dividing visible light into different signals through its internal red (R), green (G), and blue (B) sensors plus color filters. Color sensors play an extremely important role in the terminal equipment, such as calibration devices for color monitors; color printers, and plotters; paint, textile, and cosmetic manufacturing, and medical applications such as blood diagnosis, urine sample analysis, and dental surgery. The complexity of a color sensor system largely depends on the number of wavelength bands or signal channels used to determine the color. There are many types of such systems, ranging from relatively simple three-channel colorimeters to multi-band spectrometers.

With the development of modern industrial production towards high-speed and automation, the color recognition work that has been dominated by the human eye for a long time in the production process will be increasingly replaced by corresponding color sensors. E.g: The library uses colors to distinguish documents for classification, which can greatly improve shelf management and statistics. In the packaging industry, product packaging uses different colors or decorations to express different properties or uses.

Ⅱ How the color sensor works?

Color sensors are divided into three different types: light to photocurrent conversion, light to analog voltage conversion, and light to digital conversion. The former usually only represents the input part of the actual color sensor, because the amplitude of the original photocurrent is very low and always requires amplification to convert the photocurrent to a usable level. Therefore, the most practical analog output color sensor will have at least one transimpedance amplifier and provide voltage output.

1.Light to photocurrent sensor

The light-to-photocurrent sensor is composed of a photodiode or a photodiode with a color filter. The photodiode is similar to a light-emitting diode. The core is also a p-n junction, but the photodiode is a converter that converts light energy into electrical energy. There is a window on the photodiode housing that allows light to illuminate the photosensitive area, and the photodiode works under reverse voltage. When there is no light, only a weak reverse leakage current-dark current flows through the reverse-biased p-n junction. When the valence electrons in each region of the PN junction absorb the photon energy, they break free and become free electrons. At the same time, a hole is generated. These free electrons and holes are generated by light are called photo-generated carriers.

In the p-region and n-region away from the depletion layer, due to the weak electric field strength, the photogenerated carriers can only perform diffusion motion. They disappear due to recombination during the diffusion process, and it is impossible to form a photocurrent. However, due to the high electric field strength in the depletion layer, the photogenerated free electrons and holes will move to the n-region and p-region at a large speed under the action of the electric field and reach the electrode to move along the external circuit, forming a photocurrent. The direction is from the cathode to the anode of the photodiode. An external circuit can be used to convert the photocurrent into a proportional voltage output, and then the voltage can be converted into a digital format by an analog-to-digital converter and sent to the microcontroller. The traditional method of color sensing is to use a structure that combines three to four photodiodes on a chip and places red, green, and blue filters on the surface of the photodiode. An independent transimpedance amplifier feeds the output of each photodiode to an A/D converter with a typical resolution of 82 bits.

Therefore, the light-to-photocurrent converter is suitable for applications that require short response time, customized gain and speed adjustment and work under changing light conditions.

2.Light to analog voltage sensor

light to the analog voltage sensor

The light to analog voltage sensor consists of a photodiode array with color filters and integrates a transimpedance amplifier. An external circuit is required to convert the analog voltage into a digital output before it can be sent to the digital signal processor. The light to analog voltage color sensor is composed of a photodiode array behind the color filter and an integrated current-to-voltage conversion circuit (usually a transimpedance amplifier). The light falling on each photodiode is converted into photocurrent, whose amplitude depends on the brightness and wavelength of incident light (due to color filters). Without a color filter, a typical silicon photodiode would respond to wavelengths from the ultra-violet region to the visible region. In the part of the spectrum close to infrared, the peak response region lies between 800nm and 950nm. The red, green, and blue transmissive color filters will reshape and optimize the spectral response of the photodiode. A properly designed filter will provide a spectral response to the filtered photodiode array that mimics the human eye. The photocurrent of each of the three photodiodes is converted into VRout, VCout, and VBout using a current-to-voltage converter. Therefore, the light to analog voltage converter is suitable for applications that require shorter design cycles, faster product development cycles, and well-designed light conditions and space utilization.

3.Light to digital voltage sensor

It is composed of a photodiode array with a filter, an analog-to-digital converter, and a digital core for communication and sensitivity control. The output allows direct interface to a microcontroller or other logic control channels, such as a 2-wire serial interface to further process the signal without additional devices.

Take the decorative lighting of the RGB color sensor as an example:

1) Use color sensors to measure LED brightness changes over time, provide optical feedback, and control the color point of the light source.

2) Can be combined with color controller technology to form a closed-loop color management system.

Therefore, the number of components required by this method is less than that of discrete photodiodes. Because the noise-sensitive analog circuit is located on the chip, the space occupied by the circuit board is compressed, the installation cost is reduced, and the design and circuit are simplified.

Ⅲ Application of color sensor

1. Introduction to TCS230

TCS230 is a programmable color light to the frequency converter. It integrated a configurable silicon photodiode and a current-to-frequency converter on a single CMOS circuit and integrated red, green, and blue (RGB) filters on a single chip. It was the first RGB color sensor that has a digital compatible interface. The output signal of TCS230 is digital, which can drive standard TTL or CMOS logic inputs, so it can be directly connected with microprocessors or other logic circuits. Since the output is digital and can achieve conversion accuracy of more than 10 bits per color channel, there is no need for an A/D conversion circuit.

2. The internal structure and working principle of TCS230

TCS230 adopts an 8-pin SOIC surface-mount package, with 64 photodiodes integrated on a single chip. These diodes are divided into four types. Among them, 16 photodiodes have a red filter; 16 photodiodes have a green filter; 16 photodiodes have a blue filter; the remaining 16 have no filters and can transmit all light information.

(A) TCS230 package form

(B) Block diagram of the internal structure of TCS230

These photodiodes are arranged in a cross in the chip, which can minimize the unevenness of incident light radiation, thereby increasing the accuracy of color recognition. On the other hand, 16 photodiodes of the same color are connected in parallel and distributed evenly in the diode array, the color position error can be eliminated. When working, the required filter is dynamically selected through two programmable pins.

The typical output frequency of the sensor ranges from 2Hz to 500kHz. Users can also select 100%, 20%, or 2% output scale factor, or power-off mode through two programmable pins. The output scale factor enables the output of the sensor to adapt to different measurement ranges and improves its adaptability. For example, when using a low-speed frequency counter, you can select a small scale value to match the output frequency of the TCS230 with the counter.

3. Color recognition module based on TCS230

The color recognition module based on TCS230 is as shown in the figure below. The size is 72*16*12 cubic millimeters. It is equipped with 4 high-power white LED lights, which can identify the components of the three primary colors of R, G, and B. Through the mixing of these three primary colors, color can be recognized. The working voltage is 5V, the current is 0.12V. The output pin can be directly connected to the I/O port of the microcontroller.

The TCS230 module has 3 color filters. The theory of three primary colors shows that various colors are mixed with different proportions of the three primary colors. When one of the color filters is selected, it only allows a specific primary color to pass through and prevents other colors from passing. For example, when the blue filter is selected, only blue in the incident light can pass, both red and green are blocked. At this time, the pulse output pin of TCS230 will output pulses of a certain frequency, and the intensity of blue light can be obtained from the number of pulses. Similarly, when other filters are selected, the light intensity of the green light and red light can be obtained. Through these three values, we can analyze the color of the light projected on the TCS230 sensor. The selection of the color filter is determined by the S2 and S3 pins of the module.

Therefore, by connecting modules S2 and S3 with the I/O ports of the controller, you can conveniently control the selection of the filter. At the same time, connecting the pulse output pin of the module to the external interrupt of the controller, the pulse output number of the module can be obtained by means of external interruption, so as to obtain the components of the three primary colors and analyze the color of the object.

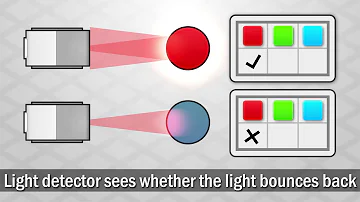

1.What is a color sensor?

A color sensor is a type of "photoelectric sensor" which emits light from a transmitter and then detects the light reflected back from the detection object with a receiver.

2.What are color sensors used for?

It can recognize and detect colors and has many good new features in comparison with other color sensors. It is adequate for colorimeter measurement applications, such as medical diagnosis, color printing, computer color monitor calibration, and cosmetics, paint, textile, and the process control of printing materials.

3.What are the main parts of a color sensor?

Most industrial color sensors contain a white light emitter and three separate receivers. There are usually three sets of color source or color filter with peak sensitivities at wavelengths that we identify as red (580nm), green (540nm), and blue (450nm). All colors can be derived by their components.

4.What is an RGB sensor?

Colour sensors are employed to recognize/detect the color of the material in RGB (red, green, blue) scale while rejecting the unwanted infrared or ultraviolet light.

5.Where is the color sensor used?

Color sensors are generally used for two specific applications: true color recognition and color mark detection. Sensors used for true color recognition are required to "see" different colors or to distinguish between shades of a specific color. They can be used in either a sorting or matching mode.

The Key Role of Electronic Components in IoT DevicesUTMEL01 September 20234585

The Key Role of Electronic Components in IoT DevicesUTMEL01 September 20234585The article discusses the pivotal role of electronic components in Internet of Things (IoT) devices. IoT devices work by capturing real-world data using sensors, processing it through a microcontroller, and then sending it to the cloud for further analysis.

Read More How to Identify the Perfect Proximity Sensor for Your ApplicationUTMEL19 July 2025468

How to Identify the Perfect Proximity Sensor for Your ApplicationUTMEL19 July 2025468Find the best proximity sensors for your project by evaluating material, sensing range, environment, and system needs to ensure optimal performance and reliability.

Read More Trusted Vibration Sensors for Homeowners and Industry ProfessionalsUTMEL17 July 2025394

Trusted Vibration Sensors for Homeowners and Industry ProfessionalsUTMEL17 July 2025394Compare top vibration sensors for home and industrial use. Find trusted options for security, predictive maintenance, and equipment protection.

Read More Wiring and Mounting Photoelectric Sensors in 2025UTMEL15 July 2025466

Wiring and Mounting Photoelectric Sensors in 2025UTMEL15 July 2025466Wire and mount photoelectric sensors in 2025 with step-by-step safety, wiring, and alignment tips for reliable installation and optimal sensor performance.

Read More Essential Tips for Picking the Best Gas SensorUTMEL15 July 20251174

Essential Tips for Picking the Best Gas SensorUTMEL15 July 20251174Find out how to select gas sensors by matching target gases, environment, and compliance needs for reliable and accurate gas detection in any setting.

Read More

Subscribe to Utmel !