What are Proximity Sensors?

What are Proximity Sensors and How Do They Work?

| I Introduction | |

| II How Do Proximity Sensors Work? | |

| III Classification of Proximity Sensors | 1. Capacitive Proximity Sensors |

| 2. Inductive Proximity Sensors | |

| 3. Photoelectric Proximity Sensors | |

| 4. Ultrasonic Proximity Sensors | |

| IV Applications of Proximity Sensors | 1. Application in ATM Cash Machine Monitoring |

| 2. Application in Aircraft Landing Gear Systems | |

| 3. Application in Railway Track Monitoring | |

| 4. Application in Automatic Packaging Machinery | |

| 5. Application in Robot Hand Grippers | |

| 6. Application in Automotive Electronics | |

| 7. Application in Screen Doors | |

| 8. Application in Touchscreen Mobile Phones | |

| 9. Application in Industry 4.0 and Smart Manufacturing | |

| V Market Trends and Future Outlook | |

I Introduction

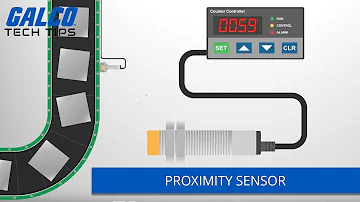

The proximity sensor is a comprehensive term for sensors that replace contact detection methods such as limit switches. It aims to detect without physically contacting the detection object. These sensors can detect the movement information and presence information of objects and convert them into electrical signals. A proximity sensor is a device with the ability to sense the proximity of an object. It uses displacement sensor sensitivity to detect the approach of objects and outputs corresponding switch signals. Therefore, proximity sensors are commonly referred to as proximity switches.

Proximity sensors have become increasingly vital in modern automation and consumer electronics. As contactless detection technology, they offer significant advantages including reduced wear, extended lifespan, and enhanced reliability compared to mechanical switches. Their applications span from industrial automation to everyday consumer devices, making them indispensable components in contemporary technology.

II How Do Proximity Sensors Work?

The working principle of proximity sensors involves sending light or electromagnetic waves from a source into a modulator. The measured parameter interacts with the signal entering the modulation area, resulting in changes in the signal's properties (such as intensity, wavelength, frequency, phase, or polarization state), creating what is called the modulated signal. Functional-type proximity sensors are made with sensitive characteristics or functions inherent to their design. Transmission-type proximity sensors primarily serve to transmit signals, with other sensitive elements installed near the endpoint or in the middle to detect the measured changes.

Proximity sensor

Among all types of switches, proximity sensors have components with the ability to "perceive" objects approaching them using displacement sensor technology. The proximity sensor uses the sensitive characteristics of displacement sensors to detect approaching objects, thereby achieving the purpose of controlling switches on or off.

When an object moves toward the proximity sensor and approaches within a certain distance, the displacement sensor perceives it and the switch actuates. This distance is called the "detection distance" or "sensing range". Different proximity sensors have varying detection distances, ranging from a few millimeters to several meters depending on the technology and application.

Sometimes detected objects move toward the proximity sensor one by one at certain time intervals, then leave in sequence, repeating this process continuously. Different proximity sensors have different response capabilities to detected objects. This response characteristic is called the "response frequency" or "switching frequency", which is crucial for high-speed automated production lines.

III Classification of Proximity Sensors

1. Capacitive Proximity Sensors

Capacitive proximity sensors are electric capacitance switches that use electrodes as detection terminals. They consist of a high-frequency oscillation circuit, detection circuit, amplifier circuit, shaping circuit, and output circuit.

Capacitive proximity sensors

There is a certain capacitance between the detection electrode and ground, which becomes an integral part of the oscillation circuit. When a detected object approaches the detection electrode, the electrode experiences electrostatic induction, causing a polarization phenomenon due to the applied voltage. The closer the detected object is to the detection electrode, the more induced charge accumulates. The electrostatic capacitance on the detection electrode is C = Q/V. Therefore, as the charge increases, the detection electrode capacitance C increases correspondingly.

The oscillation frequency of the oscillation circuit is f = 1/(2π√LC), which is inversely proportional to the capacitance. When capacitance C increases, the oscillation weakens or even stops. The two states of oscillation and stopped oscillation are converted into switching signals by the detection circuit and output externally.

Capacitive sensors can detect both metallic and non-metallic objects, including liquids, powders, and granular materials. This versatility makes them particularly useful in food processing, pharmaceutical, and chemical industries. They are commonly used for level detection in tanks and containers, detecting objects through non-metallic walls, and proximity detection in challenging environmental conditions.

2. Inductive Proximity Sensors

Inductive proximity sensors consist of a high-frequency oscillation circuit, detection circuit, amplifying circuit, shaping circuit, and output circuit. The sensitive element for detection is the detection coil, which is an integral part of the oscillation circuit. The oscillation frequency of the oscillation circuit is f = 1/(2π√LC).

When alternating current flows through the detection coil, it generates an alternating magnetic field around the coil. When a metal object approaches the detection coil, eddy currents are induced in the metal object, which absorb magnetic field energy and change the inductance L of the detection coil. As a result, the oscillation frequency of the oscillation circuit decreases, and oscillation eventually stops. These two states—oscillation and stopped oscillation—are converted into switch signal outputs by the monitoring circuit.

Inductive proximity sensors

It is important to note that objects detected by inductive proximity sensors must be metal conductors; non-metallic objects cannot be measured using this method. The amplitude change varies with the type of target metal, so detection distance also varies accordingly. Ferrous metals (iron, steel) typically provide the longest detection distances, while non-ferrous metals (aluminum, copper, brass) provide shorter ranges.

Market Insight: Inductive proximity sensors dominate the market with approximately 32-35% market share as of 2024-2025, primarily due to their robustness in metal-rich industrial settings and harsh environments. They remain the preferred choice for industrial automation, robotics, and manufacturing applications.

3. Photoelectric Proximity Sensors

In photoelectric proximity sensors, the beam axis of the light-emitting diode and the axis of the phototransistor lie on the same plane and form a specific angle. The two axes intersect at a point in front of the sensor. When the surface of the detected object is near the intersection point, light reflected from the light-emitting diode is received by the phototransistor, generating an electrical signal. When the object is far from the intersection point, the reflection area is not within the viewing angle of the phototransistor, and the detection circuit produces no output.

Typically, the drive current sent to the light-emitting diode is not direct current, but alternating current of a certain frequency. Consequently, the receiving circuit obtains an alternating signal of the same frequency. If the received signal is filtered to allow only signals of the same frequency to pass, this effectively prevents interference from other stray light and enhances the luminous intensity of the light-emitting diode.

Photoelectric proximity sensors

Photoelectric sensors are versatile and can detect objects regardless of material type—metallic, non-metallic, transparent, or opaque. They offer longer detection ranges compared to inductive and capacitive sensors, with some models capable of detecting objects several meters away. Common configurations include through-beam, retro-reflective, and diffuse reflection types, each suited for different applications.

4. Ultrasonic Proximity Sensors

Ultrasonic proximity sensors emit high-frequency sound waves (typically 40-200 kHz) and measure the time it takes for the echo to return after reflecting off an object. The distance is calculated using the formula: Distance = (Speed of Sound × Time) / 2. These sensors can detect objects regardless of color, transparency, or surface finish, making them ideal for applications where optical sensors might fail.

Ultrasonic sensors excel in detecting liquids, clear materials, and objects with irregular surfaces. They are commonly used in parking assistance systems, tank level monitoring, and robotic obstacle detection. The detection range typically spans from a few centimeters to several meters, with high accuracy in most environmental conditions. However, they can be affected by extreme temperatures, air currents, and highly sound-absorbing materials like foam or fabric.

Growing Technology: Ultrasonic proximity sensors represent one of the fastest-growing segments in the proximity sensor market (2024-2032), driven by expanding applications in automotive safety systems, smart infrastructure, and healthcare. Their ability to detect both metallic and non-metallic objects, including liquids, makes them more versatile than inductive sensors.

IV Applications of Proximity Sensors

1. Application in ATM Cash Machine Monitoring

Human body proximity sensors are control devices for detecting human body proximity, which can accurately detect the approach of nearby people. They are currently excellent choices for alarm systems and status detection. The sensing component has high detection sensitivity to the movement of nearby people and strong anti-interference capability against ambient sound signals. Internal micro-circuit chips provide program control processing with high detection sensitivity and trigger reliability. The detection and control components are integrated into one unit with low standby power consumption.

Since sensitivity to human bodies is continuously adjustable, these sensors are suitable for many different applications. In security and anti-theft systems, such as data files, accounting, finance, museums, and vaults, anti-theft devices typically incorporate various proximity sensors. Modern ATMs use these sensors not only for security monitoring but also to activate display backlights, initiate user interfaces, and trigger surveillance cameras when customers approach.

2. Application in Aircraft Landing Gear Systems

The aviation power plant, landing gear system, and navigation system are the three systems with the highest service difficulty reports from airlines. Failures in the landing gear system can cause abnormal events such as aircraft returns and alternate landings, bringing economic losses to companies and posing aviation safety hazards.

Aircraft landing gear

In typical Airbus landing gear control systems, digital fly-by-wire control systems are employed. The basic principle involves sending sensor signals to the control box, which then issues commands to actuators after comprehensive calculation and comparison. The control link features redundancy control for safety.

Modern civil aircraft landing gear retraction systems include both normal retraction and emergency release systems. The landing gear control system uses fly-by-wire manipulation and achieves cross-linking with other systems. Inductive proximity sensors are widely used to detect landing gear positions.

Each landing gear has two main sensors: the lock-up sensor and the lock-down sensor, which switch transmission position signals when the landing gear is locked in the up or down position. These sensors are magnetoresistive proximity sensors, primarily composed of the sensor body and sensor excitation plate.

The sensor body converts electrical energy into a magnetic field. The excitation plate primarily increases magnetic permeability. When the landing gear approaches the excitation plate within a certain distance, magnetic permeability increases, and the sensor sends a signal to indicate the landing gear position. The distance between them directly affects instruction accuracy, and adjustment requirements are strict. Different aircraft models have slight variations, requiring reference to the specific Aircraft Maintenance Manual (AMM) when adjusting.

Using inductive proximity sensors to detect landing gear positions improves sensor lifespan. Additionally, information transmission and sharing with avionics systems is conveniently realized through control computers, enhancing overall system reliability and maintainability.

3. Application in Railway Track Monitoring

In railway accidents, train collisions account for a large proportion. Using proximity sensors to monitor passing trains at intersections has become a very important component in improving railway safety.

Non-contact position measurement capability allows proximity sensors to be installed symmetrically at both ends of rails at intersections. When trains pass, proximity sensors at both ends detect changes caused by wheels. Each sensor signal is analyzed by the crossing monitoring microprocessing system to determine vehicle direction and state (passing, stopped, or stationary). Information is then sent to the traffic control center via cable or wireless communication for train dispatching.

Modern railway systems increasingly integrate proximity sensors with GPS and communication technologies to create comprehensive train positioning and collision avoidance systems. These integrated solutions provide real-time tracking, automatic speed control, and enhanced safety protocols for both freight and passenger rail networks.

4. Application in Automatic Packaging Machinery

Mechanized manufacturing has created the need for automatic packaging technology, as manual packaging methods cannot meet mass production requirements. Under control system guidance, automatic packaging machines complete series of packaging processes, improving packaging efficiency and reducing costs. However, package defects are inevitable, making automatic packaging inspection an important quality assurance component. For ferromagnetic substances in packaging processes, using proximity sensors for non-contact detection is a common method.

Coils in proximity sensors generate alternating magnetic fields. When detected ferromagnetic objects enter this environment, eddy currents form internally due to electromagnetic induction. When the magnetic field generated by eddy currents is sufficiently large, it changes the original circuit parameters of the proximity sensor, generating signal output. Therefore, proximity sensors can identify whether magnetic or easily magnetized substances are present within a certain range. In some automatic packaging processes, such as chocolate metal foil packaging, proximity sensors detect the presence of magnetic substances to determine whether packaging errors exist or whether products are missing from the process.

In contemporary packaging lines, proximity sensors work in conjunction with vision systems and weight sensors to provide comprehensive quality control. They verify proper seal integrity, detect missing components, confirm correct positioning, and ensure package completeness at high speeds, often exceeding hundreds of packages per minute.

5. Application in Robot Hand Grippers

The robot hand gripper is a mechanical structural component with multiple degrees of freedom that can dexterously grasp objects. It is used in various industrial automated production, assembly, and operations. It can perform tasks such as information detection, item collection, and handling in high-risk environments. Robot hand grippers generally use pincer structures to grip objects through opening and closing motions. Therefore, precise measurement and control of "jaw" opening and closing is a key factor directly affecting gripping success.

Robot hand gripper

Because proximity sensors can sense changes in distance and position, they are common sensor devices for measuring opening and closing conditions in robot hand grippers. They use the relative positional relationship between magnetic field changes and the metal parts being measured. Generally, sensors are installed on one gripper clamp. When gripping objects, proximity sensors judge the distance between the two clamps by sensing magnetic field size changes. This allows comparison with set values and adjustment of hand gripper opening size.

Advanced robotic systems now incorporate multiple proximity sensors along with force sensors and vision systems to enable adaptive gripping. This allows robots to handle delicate items without damage, adjust grip pressure in real-time, and work safely alongside human operators in collaborative robotics applications.

6. Application in Automotive Electronics

Demand for proximity detection sensors in automotive electronics has been steadily increasing. Possible applications of proximity detection in the automotive electronics industry are extensive. Examples include car access control: detecting hands approaching door handles to initiate unlocking processes; illuminating and waking touchscreens when palms approach screen surfaces; and turning interior lights on/off when palms are near sensors.

Door opening system with detection function

For various automotive electronics applications, there are diverse proximity detection methods such as capacitive sensing, infrared, ultrasonic, and optical technologies. For proximity detection ranging from 5mm to 300mm, capacitive sensing technology offers many advantages over other technologies: excellent reliability, simple mechanical design, low power consumption, and low cost.

An example of capacitive proximity detection is its application in car access control systems. The proximity sensor detecting hand approach is located in the door handle (1). Once approach is detected, the main control unit (2) sends a wake-up signal through the low-frequency antenna (3), activating the car key transmitter (4). The car key transmitter then exchanges information with the RFID receiver (5). If encoded information matches the main control unit (2), the car door lock opens. The entire proximity detection and ID recognition process takes a fraction of a second.

Compared with touch detection, using proximity detection in car access control systems provides the advantage of anticipating owner identification timing. Consequently, door locks are already open before doors are pulled.

Automotive Growth: The automotive sector accounted for approximately 27% of the proximity sensor market share in 2024 and is expected to grow at the fastest rate through 2030-2032. This growth is driven by increasing adoption of Advanced Driver Assistance Systems (ADAS), parking assistance, blind-spot detection, collision avoidance, automated driving systems, and electric vehicle (EV) technologies. Proximity sensors are critical components enabling autonomous and semi-autonomous vehicle navigation and environmental awareness.

7. Application in Screen Doors

For safety, subway screen doors are increasingly used on subway platforms. Proximity switch sensors are heavily invested in screen door technical applications.

Subway screen doors

Currently, common schemes used by screen door systems to detect door opening and closing generally employ two proximity switches. Since proximity sensors can detect in a non-contact manner, detected objects are not worn or damaged. This is the main reason for their suitability for subway installation. As proximity sensor performance continues improving, they are used in more applications. In the future, they will be widely used not only for subway doors but also for other shielded doors such as those in buses, elevators, and automated warehouse systems.

Modern screen door systems integrate proximity sensors with safety interlock systems, obstacle detection, and emergency override mechanisms. These sensors work in milliseconds to prevent door closure when obstructions are detected, significantly enhancing passenger safety in high-traffic transit systems worldwide.

8. Application in Touchscreen Mobile Phones

The use of MEMS technology in proximity sensors has gained popularity in smartphones. At the beginning of touchscreen phone popularity, users discovered a touchscreen flaw: when picking up phones with common gestures, faces often touched touchscreens, accidentally clicking hang-up buttons or hands-free buttons, causing unnecessary embarrassment. Therefore, mobile phone manufacturers used MEMS technology to design MEMS proximity sensors into touchscreen phones, which automatically lock screens when answering calls to avoid false triggers. Additionally, backlights can turn off while screens are locked, effectively saving energy and extending standby time.

Touchscreen mobile phone

Smartphones use MEMS ambient light sensors and proximity sensors for ambient light detection and proximity detection. Ambient light detection judges surrounding brightness based on the amount of light detected by the light-receiving unit according to sensor illuminance. Proximity detection involves light emitted from the sensor's light source onto the measurement object, with distance determined based on the amount of light reflected to the proximity light-receiving unit of the sensor.

Ambient light sensors optimize LED backlight adjustment. Whether in dim movie theaters or well-lit outdoor environments, mobile phones can self-adjust to appropriate brightness in any environment. Proximity sensors turn off touchscreens when answering calls, preventing accidental button touches on screens.

Modern smartphones (as of 2024-2025) incorporate increasingly sophisticated proximity sensing capabilities. Many devices now use combinations of infrared LED emitters and detectors, with some high-end models integrating Time-of-Flight (ToF) sensors for more accurate distance measurement. These sensors typically occupy minimal space (often just a few millimeters) near the top of the screen, and some manufacturers have developed under-display proximity sensors to enable truly bezel-less designs.

Consumer Electronics Dominance: The consumer electronics segment dominates the MEMS sensor market with approximately 45% market share in 2024. Smartphones alone contain multiple MEMS-based sensors including proximity sensors, accelerometers, gyroscopes, fingerprint sensors, ambient light sensors, magnetometers, and barometers. The global MEMS for mobile devices market was valued at USD 7.22 billion in 2024 and is projected to reach USD 16.33 billion by 2033, growing at a CAGR of 9.5%.

9. Application in Industry 4.0 and Smart Manufacturing

One of the major applications of proximity sensors in Industry 4.0 is predictive maintenance and machine monitoring. Inductive proximity sensors measure distance variations between shafts and support bearings, constituting vital information for vibration monitoring of machines. This enables early detection of bearing wear, misalignment, and other mechanical issues before they cause costly downtime or catastrophic failures.

In smart manufacturing environments, proximity sensors integrate with IoT networks and AI-powered analytics platforms. They provide real-time data on machine status, production flow, and quality control. Connected sensors enable immediate alerts when anomalies are detected, facilitate remote monitoring and diagnostics, and contribute to overall equipment effectiveness (OEE) improvements.

Modern proximity sensors in industrial settings often feature IO-Link connectivity, enabling digital communication with PLCs and SCADA systems. This allows for remote configuration, diagnostic information retrieval, and seamless integration into Industry 4.0 architectures. Manufacturers report efficiency gains of 15-20% and cost reductions of up to 30% through 5G-enabled monitoring systems incorporating advanced proximity sensors.

Proximity sensors also play crucial roles in automated guided vehicles (AGVs), autonomous mobile robots (AMRs), and collaborative robots (cobots). They provide essential environmental awareness, enabling safe navigation in dynamic manufacturing environments and collision avoidance when working alongside human operators.

V Market Trends and Future Outlook

Global Market Growth

The global proximity sensor market has experienced substantial growth and is projected to continue expanding significantly:

Market Size 2024: USD 4.3-4.9 billion

Projected Market Size 2030-2033: USD 6.6-9.01 billion

Compound Annual Growth Rate (CAGR): 5.7-8.0% (2024-2033)

Key Market Drivers

Industrial Automation: Increasing adoption of automation in manufacturing to improve productivity and reduce labor costs

Automotive Safety: Growing implementation of ADAS, autonomous driving technologies, and stringent safety regulations

Consumer Electronics: Rising demand in smartphones, tablets, wearables, and IoT devices

Smart Cities: Expansion into smart infrastructure, building automation, and environmental monitoring

IoT Integration: Integration with Internet of Things and AI technologies for enhanced functionality

Regional Insights

Asia-Pacific leads the market with approximately 36% of global revenue in 2024, driven by:

China's factory digitalization and "China Manufacturing 2025" initiative

Japan's robotics leadership

South Korean electronics manufacturing

India's growing automotive industry

North America holds approximately 21% market share with strong adoption in automotive safety systems, industrial automation, and advanced manufacturing.

Europe demonstrates robust growth driven by automotive innovation, industrial automation requirements, and smart city initiatives.

Technology Trends

Miniaturization: Continued development of smaller, more compact sensors using advanced MEMS technology

Enhanced Sensitivity: Higher detection sensitivity and improved accuracy through advanced signal processing

Energy Efficiency: Ultra-low power consumption designs for battery-powered IoT and wearable devices

Hybrid Sensors: Integration of multiple detection principles (e.g., ultrasonic-photoelectric combinations)

Smart Connectivity: IO-Link, wireless protocols, and cloud connectivity for Industry 4.0 applications

AI Integration: Machine learning algorithms for improved object recognition and adaptive sensing

What are the types of proximity sensors?

According to its object detection method, there are four widely-used types of proximity sensors, as well as some newer high-end designs: Inductive Proximity Sensors. Capacitive Proximity Sensors. Ultrasonic proximity Sensors. IR Proximity Sensors. High-end Proximity Sensors.

Where are proximity sensors used?

Proximity sensors are used in phones, recycling plants, self-driving cars, anti-aircraft systems, and assembly lines. There are many types of proximity sensors, and they each sense targets in distinct ways.

What is the working principle of proximity sensor?

Inductive Proximity Sensors detect magnetic loss due to eddy currents that are generated on a conductive surface by an external magnetic field. An AC magnetic field is generated on the detection coil, and changes in the impedance due to eddy currents generated on a metallic object are detected.

Why is proximity sensor used?

A proximity sensor is a sensor able to detect the presence of nearby objects without any physical contact. Proximity sensors are also used in machine vibration monitoring to measure the variation in distance between a shaft and its support bearing.

How accurate are proximity sensors?

Today's quality inductive proximity sensors can have trigger points that are repeatable to 0.0001 in. To obtain such precision, though, the detectable object must be moved the reset distance away from the sensor after each time the sensor is triggered.

The Key Role of Electronic Components in IoT DevicesUTMEL01 September 20234981

The Key Role of Electronic Components in IoT DevicesUTMEL01 September 20234981The article discusses the pivotal role of electronic components in Internet of Things (IoT) devices. IoT devices work by capturing real-world data using sensors, processing it through a microcontroller, and then sending it to the cloud for further analysis.

Read More How to Identify the Perfect Proximity Sensor for Your ApplicationUTMEL19 July 2025889

How to Identify the Perfect Proximity Sensor for Your ApplicationUTMEL19 July 2025889Find the best proximity sensors for your project by evaluating material, sensing range, environment, and system needs to ensure optimal performance and reliability.

Read More Trusted Vibration Sensors for Homeowners and Industry ProfessionalsUTMEL17 July 2025600

Trusted Vibration Sensors for Homeowners and Industry ProfessionalsUTMEL17 July 2025600Compare top vibration sensors for home and industrial use. Find trusted options for security, predictive maintenance, and equipment protection.

Read More Wiring and Mounting Photoelectric Sensors in 2025UTMEL15 July 2025797

Wiring and Mounting Photoelectric Sensors in 2025UTMEL15 July 2025797Wire and mount photoelectric sensors in 2025 with step-by-step safety, wiring, and alignment tips for reliable installation and optimal sensor performance.

Read More Essential Tips for Picking the Best Gas SensorUTMEL15 July 20251880

Essential Tips for Picking the Best Gas SensorUTMEL15 July 20251880Find out how to select gas sensors by matching target gases, environment, and compliance needs for reliable and accurate gas detection in any setting.

Read More

Subscribe to Utmel !