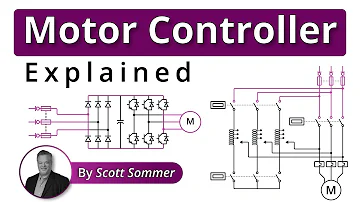

What is a Motor Starter?

Motor Starter Explained | Motor Starter Types

Catalog

Ⅰ Why do we need a motor starter?

A motor starter is essential for the safe operation of induction motors, primarily due to the physics of the rotor's low impedance at a standstill. The impedance of the rotor is directly related to the induction motor slip—the relative speed difference between the rotor and the stator magnetic field.

At a standstill (rest position), the slip is at its maximum (i.e., 1), resulting in minimal impedance. Consequently, if connected directly to full voltage, the motor draws a massive surge of energy known as inrush current. This high current heavily magnetizes the air gap, inducing an Electromotive Force (EMF) in the rotor winding. This EMF drives current through the rotor, generating the magnetic field required for torque. As the rotor accelerates and speed increases, the slip decreases, causing the current draw to stabilize at normal operating levels.

The initial inrush current can be 5 to 8 times the rated full-load current. Without a starter, this surge poses three major risks: it can thermally damage or burn out the motor's internal windings; it causes significant mechanical shock to drive trains (belts, gears, couplings); and it can create a severe voltage dip in the power supply network, potentially tripping breakers or damaging sensitive electronics connected to the same grid.

To mitigate these risks, a motor starter restricts the initial current (or voltage) for a brief period during startup and seamlessly transitions to full power once the motor reaches a safe RPM. In modern 2025 industrial standards, starters also play a critical role in energy efficiency compliance (such as IE3/IE4 standards) and provide protection against faults like undervoltage, phase loss, and overcurrent.

While small motors (typically under 1 HP) have higher inherent impedance and can often withstand direct starts, they still require the basic overcurrent protection provided by simple DOL (Direct On-Line) starters to meet safety codes.

Ⅱ What is the Role of a Motor Starter?

A starter is a control device that acts as the gateway between the power source and the motor. Its primary role is to safely manage the ON/OFF state of electric motors, but modern iterations also serve as a hub for motor protection and data monitoring.

motor starter

Manual starters are utilized for smaller, simple applications. They feature a hand-operated lever or button to physically toggle the contacts. A key limitation of basic manual starters is safety regarding power restoration: if power fails and then returns, the motor may restart unexpectedly unless the starter is equipped with Low Voltage Protection (LVP). For this reason, manual starters are generally reserved for non-critical, low-power equipment.

Automatic starters rely on electromechanical relays and contactors to switch the motor. When the control circuit is activated (e.g., via a PLC or pushbutton), current flows through the contactor coil. This energizes the coil, creating a magnetic field that pulls the contacts closed, completing the circuit to the motor windings.

Operations are typically managed via "Start" and "Stop" buttons or remote digital signals. Pressing "Stop" de-energizes the coil, and a spring mechanism forces the contacts open, cutting power. Crucially, automatic starters provide Low Voltage Protection: in the event of a power outage, the contactor opens and stays open. The motor will not restart when power is restored until the "Start" command is manually or digitally re-issued, preventing dangerous accidental startups.

Ⅲ Types of motor starter

1. Manual motor starters

Manual motor starters are the simplest form of protection, used primarily for fractional horsepower motors in single-phase and small three-phase applications. They combine an ON/OFF switch with a thermal overload relay. While cost-effective for small pumps or fans, they lack remote control capabilities. Modern manual motor protectors (MMPs) are often used in conjunction with larger contactors to provide short-circuit protection in a compact DIN-rail footprint.

2. Magnetic motor starters

Magnetic starters use an electromagnetic coil to close the power contacts, allowing for remote operation and automatic control. This is the most common type for industrial machinery. They provide under-voltage protection (preventing automatic restarts after power loss) and are available in standard NEMA and IEC sizes. In 2025, many magnetic starters are evolving into "Smart Starters," featuring communication modules that connect to industrial networks (Ethernet/IP, PROFINET) to report status and energy usage.

3. Reversing motor starters

Reversing starters consist of two interlocked magnetic contactors: one for forward rotation and one for reverse. By swapping two of the three power phases, they change the motor's direction. To prevent short circuits, they utilize strict mechanical and electrical interlocks which ensure that both forward and reverse contactors can never be energized simultaneously.

4. Soft motor starters

Soft starters have seen significant technological advancement. Using solid-state electronics (thyristors/SCRs), they gradually ramp up the voltage to the motor, eliminating the mechanical shock and high inrush current associated with full-voltage starting. Modern soft starters now feature torque control algorithms and built-in bypass contactors to maximize efficiency once the motor is up to speed. They are essential for protecting conveyors, pumps, and fragile loads from damage during startup.

5. Combination motor starters

A combination starter aggregates the motor starter, overload protection, and a disconnect switch (with short-circuit protection via fuses or a breaker) into a single enclosed unit. This simplifies installation and ensures compliance with safety codes like the NEC, as it provides a single point of power disconnection for maintenance personnel.

Ⅳ Applications of motor starters

Motor starters are ubiquitous in industrial automation, mining, HVAC, and water treatment. Their primary engineering application is to shield the electrical infrastructure from the massive currents drawn during a "Locked Rotor" or startup condition, which can be 6 to 8 times the running current. Without this protection, fuses would blow, and breakers would trip during every normal startup attempt.

Advanced applications now leverage starters for Predictive Maintenance. By monitoring current signatures and thermal loads, modern starters can detect anomalies—such as a jammed pump impeller or a worn bearing—before they cause catastrophic failure. Thermal or electronic overload relays provide a "thermal memory," ensuring the motor is not restarted until it has cooled sufficiently, preventing winding insulation degradation.

Enclosed starters are rated for specific environments, ranging from general-purpose indoor use (NEMA 1) to watertight wash-down areas (NEMA 4X) or hazardous explosion-proof environments (NEMA 7/9).

Ⅴ Selection of motor starters

Choosing the correct motor starter involves analyzing the load characteristics, duty cycle, and environmental conditions. Manual starters are generally limited to small motors (up to 10-15 HP) where automation is not required. For larger motors, or applications requiring frequent starts and stops, magnetic or soft starters are the standard.

NEMA vs. IEC: The choice between NEMA (National Electrical Manufacturers Association) and IEC (International Electrotechnical Commission) standards remains a key decision.

• NEMA starters are robust, larger, and designed for broad applicability and long life with less precise selection required. They are often preferred in heavy industries in North America.

• IEC starters are compact, modular, and cost-effective. They require precise sizing based on the application's duty cycle (e.g., AC-3 ratings). Due to their integration capabilities and space savings, IEC starters have gained significant market share in global control panel designs.

In 2025, Connectivity is a major selection factor. Engineers now frequently specify starters that can communicate via Industrial IoT protocols (like Ethernet/IP or Modbus TCP) to provide real-time data on amperage, voltage, and fault history to central control systems.

Finally, for applications requiring precise speed control or maximum energy efficiency, a Variable Frequency Drive (VFD) may be selected over a traditional starter, although soft starters remain the cost-effective choice for constant-speed applications that simply need a smooth ramp-up.

1.When should you use a motor starter?

Starters are used to protect DC motors from damage that can be caused by very high current and torque during startup. They do this by providing external resistance to the motor, which is connected in series to the motor's armature winding and restricts the current to an acceptable level.

2.What are the types of starters?

Stator resistance starter. Autotransformer starter. Star-delta starter. Direct on-line starter. Soft Starter.

3.How do I choose a motor starter?

When choosing a motor starter, you should consider the load, the type of motor, and the network before deciding which one is best for you. Soft Starters: Soft starters steadily ramp up the speed of a motor to prevent large current surges and to minimize the amount of wear on electrical contacts in the system.

4.Does a single-phase motor need a starter?

Single-phase motors generally need a starter circuit to get them turning. That starter circuit is turned off by a centrifugal switch once the motor reaches a minimum RPM. Three-phase motors do not require a starter circuit. However, the start-up current surge can be 6 or more times the run current.

5.Does a 1 hp motor need a starter?

Motors below 1 HP (0.7457) are directly connected to the power supply without a starter because their armature resistance is very high and they have the ability to afford and pass higher current due to high resistance. So the armature windings are safe from the high starting current while staring at a motor.

What is a Servo Drive?UTMEL16 June 20215218

What is a Servo Drive?UTMEL16 June 20215218Servo drive, also known as "servo controller" and "servo amplifier", is a kind of controller used to control servo motors. Its function is similar to that of frequency converters acting on ordinary AC motors, and it is part of the servo system. The servo drive is mainly used in high-precision positioning systems. Generally, the servo motor is controlled by three methods of position, speed, and torque to achieve high-precision transmission system positioning.

Read More What is a Switched Reluctance Motor?UTMEL09 July 20248025

What is a Switched Reluctance Motor?UTMEL09 July 20248025Switched reluctance motor is a type of speed-regulating motor developed after DC motor and brushless DC motor. Product power levels range from several watts to hundreds of kilowatts, and are widely used in household appliances, aviation, aerospace, electronics, machinery, and electric vehicles.

Read More Types, Working, and Selection of DC MotorUTMEL27 March 202517041

Types, Working, and Selection of DC MotorUTMEL27 March 202517041A direct current motor (DC motor) is an electric motor that operates on direct current. The operation of an electric motor is based on basic electromagnetism. When a current-carrying conductor is put in an external magnetic field, it will feel a force that is equal to the current in the conductor and the frequency of the external magnetic field.

Read More Linear Induction Motor: Working Principle, Characteristics, and ApplicationsUTMEL02 March 202114396

Linear Induction Motor: Working Principle, Characteristics, and ApplicationsUTMEL02 March 202114396LIM stands for Linear Induction Motor, and it is an improved version of the rotary induction motor that produces linear translational motion instead of rotating motion. Other than rotating torque, this device generates linear movement and force. By cutting a radically shaped cut in the revolving induction and thus leveling the section, the design and functionality of the linear induction motor can be demonstrated in the diagram below.

Read More Stepper Motor: Types, Working and ApplicationsUTMEL26 December 20259918

Stepper Motor: Types, Working and ApplicationsUTMEL26 December 20259918A brushless, synchronous electric motor that converts digital pulses to mechanical shaft rotation is known as a stepper motor. When operated by a sequentially switched DC power supply, the normal shaft motion is made up of discrete angular motions of approximately uniform magnitude.

Read More

Subscribe to Utmel !

![2318]() 2318

2318Steinel

![R88L-EA-AF-0606-1550]() R88L-EA-AF-0606-1550

R88L-EA-AF-0606-1550Omron

![855-12128]() 855-12128

855-12128Advantech

![KN-WR2-1]() KN-WR2-1

KN-WR2-1Advantech

![852-10922]() 852-10922

852-10922Advantech

![LC20G-101 1/5]() LC20G-101 1/5

LC20G-101 1/5Nidec

![BB-ERT314]() BB-ERT314

BB-ERT314Advantech

![RTLTE-310-W-AT]() RTLTE-310-W-AT

RTLTE-310-W-ATAdvantech

![INWFIDAI001R000]() INWFIDAI001R000

INWFIDAI001R000HMS Networks

![INKNXMBM1000000]() INKNXMBM1000000

INKNXMBM1000000HMS Networks