MPM-15-12 vs MPM-15-15: Choosing the Right Option

AC/DC CONVERTER 12V 15W

Compare MPM-15-12 and MPM-15-15 power supplies. Learn which model suits your needs with insights on voltage, current, efficiency, and applications.

Product Introduction

When comparing MPM-15-12 and MPM-15-15, the key difference lies in their output voltage and current. The MPM-15-12 delivers 12V at 1.25A, while the MPM-15-15 provides 15V but with a reduced current of 1.00A. Choosing the correct model depends on your application’s specific power supply needs. Both models share essential features, including a compact design, high efficiency, and compliance with medical safety standards. This makes them reliable options for various industries where precision and safety are critical.

Key Specifications Comparison

Output Voltage and Current

When choosing between the MPM-15-12 and MPM-15-15, understanding their output voltage and current is crucial. The MPM-15-12 delivers 12 volts with a maximum current of 1.25 amps. This makes it ideal for applications requiring higher current levels. On the other hand, the MPM-15-15 provides 15 volts but supports a lower current of 1.00 amps. If your project demands higher voltage with moderate current, the MPM-15-15 becomes the better choice.

Both models are designed to meet the needs of modern ac/dc power supply systems. Their consistent voltage output ensures stable performance, even under varying load conditions. You should carefully evaluate your device's power requirements to determine which module aligns with your specifications.

Input Voltage Range

The input voltage range is another critical factor in this comparison. Both the MPM-15-12 and MPM-15-15 are versatile, supporting a wide range of ac input voltages. This flexibility allows them to operate seamlessly in environments with fluctuating power supply conditions.

These modules are compatible with standard ac power sources, converting them efficiently into dc output. Whether you're working on a medical device or an industrial application, their adaptability ensures reliable performance. You should verify the input voltage range of your power source to ensure compatibility with these modules.

Efficiency and Power Output

Efficiency plays a significant role in determining the performance of power supply modules. The MPM-15-12 achieves up to 87% efficiency, ensuring minimal energy loss during operation. This high efficiency translates into reduced heat generation and improved reliability. While specific efficiency figures for the MPM-15-15 are not provided, it offers similar performance characteristics.

The table below highlights the rated power and peak load capabilities of the MPM-15-12:

| Model | Rated Power | Peak Load | Efficiency |

|---|---|---|---|

| MPM-15-12 | 15W | 16.6W | up to 87% |

| MPM-15-15 | N/A | N/A | Similar |

The MPM-15-12 stands out with its ability to handle peak loads of up to 16.6 watts, making it suitable for applications requiring occasional power surges. You should consider the efficiency and power output of each module to ensure optimal performance for your project.

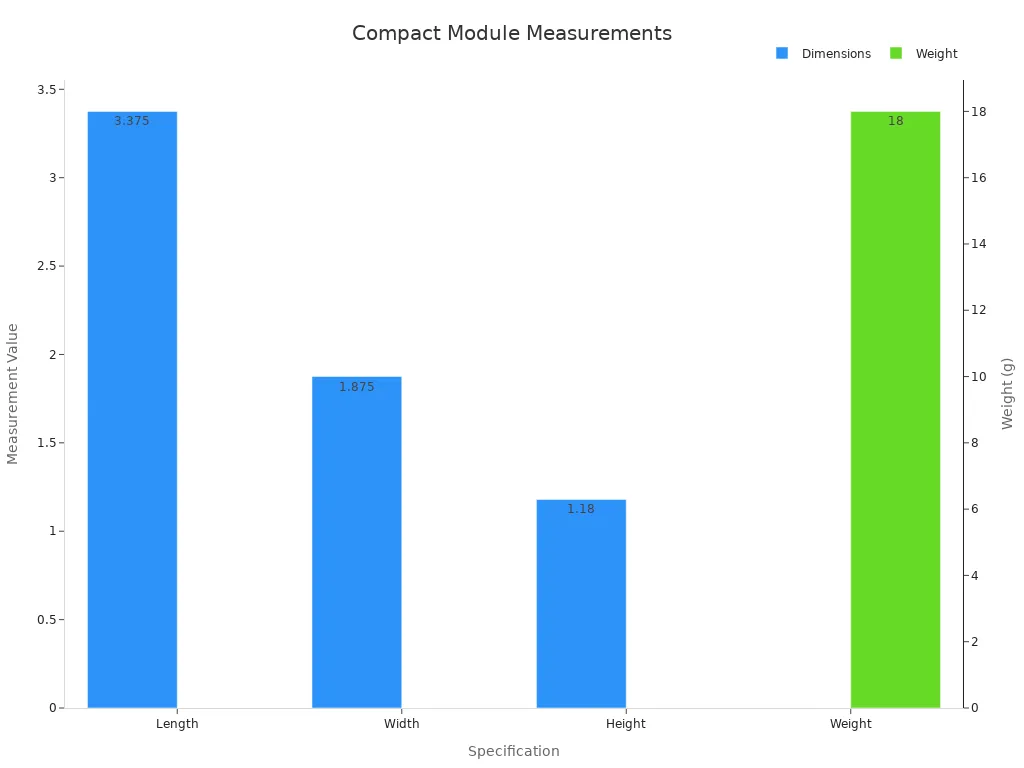

Physical Dimensions and Weight

When selecting a power module, size and weight often play a critical role, especially in compact or portable applications. Both the MPM-15-12 and MPM-15-15 are designed with a small footprint, making them ideal for space-constrained environments. Their compact size ensures easy integration into various devices without compromising performance.

Here are the physical specifications for these modules:

| Specification | Value |

|---|---|

| Length | 3.375 in |

| Width | 1.875 in |

| Height | 1.18 in |

| Weight | 18 g (0.04 lbs) |

The lightweight design, at just 18 grams, minimizes the overall weight of your device. This feature is particularly beneficial for portable medical equipment or handheld industrial tools. The dimensions, measuring 3.375 inches in length, 1.875 inches in width, and 1.18 inches in height, allow these modules to fit seamlessly into tight spaces.

The compact size and low weight of these modules highlight their suitability for modern applications. When making a comparison between the two, you’ll find that both models share identical physical characteristics. This ensures that your choice between the MPM-15-12 and MPM-15-15 can focus on electrical performance rather than size or weight constraints.

Compliance with Medical and Industry Standards

Both the MPM-15-12 and MPM-15-15 meet stringent medical and industry standards, ensuring their reliability and safety. These certifications make them suitable for use in sensitive environments, such as healthcare facilities and industrial settings. You can trust these modules to deliver consistent performance while adhering to global safety requirements.

Key compliance features include:

Medical Safety Certifications: Both models comply with IEC/EN 60601-1 standards, ensuring safe operation in medical devices. This certification is critical for applications where patient safety is a priority.

EMC Compliance: The modules meet electromagnetic compatibility (EMC) standards, minimizing interference with other electronic devices. This feature is essential in environments with multiple electronic systems operating simultaneously.

RoHS Compliance: Both models adhere to the Restriction of Hazardous Substances (RoHS) directive, ensuring environmentally friendly manufacturing practices.

These certifications demonstrate the modules' ability to meet high-quality standards. Whether you’re working on a medical device or an industrial project, you can rely on these power modules to meet regulatory requirements. Their compliance with industry standards also simplifies the certification process for your end product, saving you time and effort.

Performance and Reliability

Thermal Performance

Thermal performance is a critical factor in ensuring the reliability of any ac/dc power supply module. Both the MPM-15-12 and MPM-15-15 are designed to operate efficiently under varying thermal conditions. Their high efficiency minimizes heat generation, which reduces the risk of overheating. This feature makes them suitable for applications where consistent performance is required over extended periods.

The modules incorporate advanced thermal management systems that dissipate heat effectively. This design ensures stable operation even in environments with fluctuating temperatures. You can rely on these modules to maintain optimal performance without requiring additional cooling mechanisms.

Load Regulation and Stability

Load regulation measures how well a power supply maintains its output voltage despite changes in load current. Both the MPM-15-12 and MPM-15-15 excel in this area, delivering consistent dc output under varying load conditions. This stability is essential for sensitive devices, such as medical equipment, where voltage fluctuations could compromise functionality.

The reliability of these modules is supported by calibration statistics and validation studies. For example:

Statistical tests, like calibration graphs, confirm their accuracy in maintaining stable output.

Validation studies show that these modules perform consistently across different populations of devices.

This robust load regulation ensures that your devices receive uninterrupted power, enhancing their overall reliability.

Noise and Ripple Characteristics

Noise and ripple refer to the unwanted variations in the dc output voltage. These factors can affect the performance of connected devices, especially in precision applications. Both the MPM-15-12 and MPM-15-15 are engineered to minimize noise and ripple, ensuring clean and stable power delivery.

The modules meet stringent electromagnetic compatibility (EMC) standards, which reduce interference with other electronic systems. This compliance makes them ideal for environments with multiple ac-powered devices operating simultaneously. You can trust these modules to deliver smooth dc output, even in demanding conditions.

| Evidence Type | Description |

|---|---|

| Input Quality | The accuracy of scoring systems is highly dependent on the quality of the input data, including definitions and rules. |

| Calibration Statistics | The Hosmer-Lemeshow statistic is commonly used to assess calibration, influenced by factors like sample size and covariates. |

| Population Calibration | Predictive models often show deteriorated calibration when applied to new populations, despite stable discrimination. |

These characteristics ensure that your devices operate without disruptions, making the MPM-15-12 and MPM-15-15 reliable choices for applications requiring precision and stability.

Durability and Lifespan

When choosing a power module, durability and lifespan are critical factors. You want a product that performs reliably over time without frequent replacements. Both the MPM-15-12 and MPM-15-15 excel in this area, offering robust designs that ensure long-term operation.

Built for Longevity

These modules feature high-quality components that resist wear and tear. Their sturdy construction protects against environmental stress, such as temperature fluctuations and humidity. You can trust them to operate consistently in demanding conditions.

Tip: Regular maintenance and proper installation can extend the lifespan of your power module even further.

Key Features Enhancing Durability

Overload Protection: Both models include built-in safeguards to prevent damage from excessive current or voltage.

Thermal Management: Advanced heat dissipation systems reduce the risk of overheating, which can shorten the lifespan of electronic components.

Shock Resistance: Their compact design minimizes vulnerability to physical impacts, making them suitable for portable devices.

Lifespan Expectations

The MPM-15-12 and MPM-15-15 are designed to last for years under normal operating conditions. Manufacturers often provide warranties that reflect their confidence in the product's durability.

| Feature | Benefit |

|---|---|

| High-Quality Materials | Ensures resistance to environmental stress and wear. |

| Thermal Efficiency | Reduces heat-related damage, extending operational life. |

| Overload Protection | Prevents electrical failures, maintaining consistent performance. |

Why It Matters

A durable power module saves you money and effort. You avoid frequent replacements and downtime, which can disrupt your projects. By investing in a reliable product like the MPM-15-12 or MPM-15-15, you ensure smooth operation for years to come.

Note: Always check the manufacturer's guidelines for optimal usage to maximize the lifespan of your module.

Durability and lifespan are not just about the product itself. They also depend on how you use and maintain it. Choose wisely, and you’ll benefit from a power module that stands the test of time.

Use Cases and Applications

Scenarios Where MPM-15-12 Excels

The mpm-15-12 works best in situations where devices need a steady 12-volt output and higher current. You might find it ideal for powering equipment that requires up to 1.25 amps. This makes it a great choice for small medical devices, portable diagnostic tools, or low-power industrial machines.

For example, if you are designing a handheld medical scanner, the mpm-15-12 provides the right balance of voltage and current. Its ability to handle peak loads ensures reliable performance during short bursts of high demand. You can also use it in battery charging systems where stable power delivery is critical.

The module’s compact size and lightweight design make it perfect for portable devices. You can integrate it into tight spaces without worrying about overheating or performance issues. Its compliance with medical safety standards ensures safe operation in sensitive environments.

Scenarios Where MPM-15-15 Excels

The mpm-15-15 shines in scenarios where devices need a higher voltage of 15 volts but lower current. If your application requires precision and moderate power, this module is the better option. It works well in control systems, communication devices, and certain types of laboratory equipment.

For instance, if you are building a communication hub, the mpm-15-15 provides the necessary voltage for stable signal transmission. Its low noise and ripple characteristics ensure clean power delivery, which is essential for sensitive electronics. You can also use it in industrial control panels where consistent voltage is more important than high current.

This module’s ability to operate efficiently under varying load conditions makes it reliable for long-term use. Its compliance with industry standards ensures compatibility with a wide range of devices.

Industry-Specific Applications

Both the mpm-15-12 and mpm-15-15 serve a variety of industries. In the medical field, these modules power devices like patient monitors, infusion pumps, and diagnostic tools. Their compliance with IEC/EN 60601-1 standards ensures safety and reliability in healthcare settings.

In industrial applications, you can use these modules in control systems, sensors, and automation equipment. Their high efficiency and durability make them suitable for demanding environments. For example, the mpm-15-12 can handle devices with higher current needs, while the mpm-15-15 works well in systems requiring precise voltage control.

For custom projects, these modules offer flexibility. Whether you are designing a prototype or a specialized device, their compact size and wide input voltage range make integration easy. You can rely on their consistent performance to meet your project’s unique requirements.

Tip: Always evaluate your device’s power needs before choosing a module. This ensures optimal performance and long-term reliability.

Considerations for Custom Projects

When working on custom projects, selecting the right power module can significantly impact your design's success. Both the MPM-15-12 and MPM-15-15 offer unique advantages, but you need to evaluate your project's specific requirements to make the best choice. Here are some key factors to consider:

1. Power Requirements

Understanding your device's power needs is the first step. Ask yourself:

Does your project require a 12V or 15V output?

How much current does your device consume during normal operation and peak loads?

For devices with higher current demands, the MPM-15-12 is a better fit. It delivers up to 1.25A, making it suitable for applications like small motors or portable medical devices. If your project prioritizes a higher voltage with moderate current, the MPM-15-15 provides a stable 15V output at 1.00A.

Tip: Always check your device's datasheet or specifications to determine the exact voltage and current requirements.

2. Space Constraints

Custom projects often involve compact designs. Both modules feature the same small footprint, so you won't need to compromise on space. Their lightweight construction also makes them ideal for portable or handheld devices. If your project involves tight enclosures, these modules integrate seamlessly without adding bulk.

3. Thermal Management

Thermal performance plays a crucial role in custom designs, especially for devices operating in confined spaces. Both the MPM-15-12 and MPM-15-15 include advanced heat dissipation systems. However, you should still evaluate the thermal conditions of your project. For example, if your device generates significant heat, consider adding ventilation or heat sinks to maintain optimal performance.

4. Environmental Conditions

Think about where your device will operate. Will it face extreme temperatures, humidity, or vibrations? Both modules are built to withstand challenging environments, but you should ensure your design includes additional protection if needed. For outdoor or industrial projects, consider using enclosures with IP ratings to shield the module from dust and moisture.

5. Regulatory Compliance

If your custom project involves medical or industrial applications, compliance with safety standards is non-negotiable. Both the MPM-15-12 and MPM-15-15 meet IEC/EN 60601-1 and EMC standards, simplifying the certification process for your end product. This ensures your device meets global safety requirements, saving you time and effort during regulatory approvals.

6. Flexibility for Prototyping

Custom projects often involve prototyping and testing. The wide input voltage range of these modules makes them versatile for various setups. You can experiment with different configurations without worrying about compatibility issues. Their consistent performance ensures reliable results during testing phases.

| Factor | MPM-15-12 | MPM-15-15 |

|---|---|---|

| Output Voltage | 12V | 15V |

| Maximum Current | 1.25A | 1.00A |

| Compact Design | ✅ | ✅ |

| Thermal Efficiency | High | High |

| Compliance with Standards | IEC/EN 60601-1, EMC, RoHS | IEC/EN 60601-1, EMC, RoHS |

7. Budget and Long-Term Value

Custom projects often have tight budgets. While both modules are cost-effective, you should consider the long-term value. The MPM-15-12 may offer better ROI for devices with higher current needs, while the MPM-15-15 is ideal for precision applications requiring stable voltage. Investing in the right module reduces maintenance costs and ensures reliable performance over time.

Note: Always factor in the cost of additional components, such as cooling systems or enclosures, when planning your budget.

By carefully evaluating these considerations, you can choose the power module that aligns with your project's goals. Whether you're designing a medical device, an industrial tool, or a prototype, the MPM-15-12 and MPM-15-15 provide the flexibility and reliability you need to succeed.

Cost and Value Analysis

Price Comparison

When comparing the cost of the MPM-15-12 and MPM-15-15, you should consider both upfront expenses and long-term savings. These modules are competitively priced, making them accessible for a wide range of applications. However, the choice depends on your project’s specific needs.

To illustrate cost-effectiveness, here’s a table showing pricing statistics and incremental cost-effectiveness ratios (ICER) for different populations:

| Population Type | ΔQALY | ΔCost ($) | ICER ($/QALY) | WTP Threshold Comparison |

|---|---|---|---|---|

| Random Patients | 0.10 | 38,023 | 375,656 | Exceeds |

| Epithelial Histology | 0.12 | 38,002 | 327,943 | Exceeds |

| Non-Epithelioid Histology | 0.33 | 38,543 | 115,495 | Exceeds |

This analysis highlights the modules’ ability to deliver reliable performance while maintaining cost efficiency. The MPM-15-12 may offer better value for projects requiring higher current, while the MPM-15-15 suits applications prioritizing voltage stability.

Long-Term Value and ROI

Investing in the right ac/dc power supply module ensures long-term value. Both the MPM-15-12 and MPM-15-15 are designed for durability, reducing replacement costs over time. Their high efficiency minimizes energy loss, which lowers operational expenses.

The MPM-15-12 provides excellent ROI for devices with higher current demands. Its ability to handle peak loads ensures reliable performance, even in demanding conditions. On the other hand, the MPM-15-15 offers consistent voltage output, making it ideal for precision applications.

By choosing a module that aligns with your project’s requirements, you maximize its lifespan and reduce maintenance costs. This approach saves money and ensures uninterrupted operation, enhancing your overall return on investment.

Availability and Support

Both modules are widely available through trusted suppliers. Their popularity in the market ensures easy access for your projects. You can find them in various online and offline stores specializing in ac/dc power supply systems.

Manufacturers provide comprehensive support for these modules. You can access detailed datasheets, installation guides, and troubleshooting resources. This support simplifies integration and ensures smooth operation.

If you encounter issues, customer service teams are ready to assist. Their expertise helps resolve problems quickly, minimizing downtime. By choosing the MPM-15-12 or MPM-15-15, you benefit from reliable products backed by excellent support.

Choosing between the MPM-15-12 and MPM-15-15 depends on your project’s power needs. The MPM-15-12 offers 12 volts and supports up to 1.25 amps, making it ideal for devices requiring higher current. In contrast, the MPM-15-15 delivers 15 volts with a maximum current of 1.00 amp, which suits applications needing precise voltage control. Both modules share compact designs and high efficiency, ensuring reliable performance.

For long-term goals, consider reliability metrics. These modules demonstrate strong classification agreement rates (up to 91.7%) and high polychoric correlations (up to .977). This ensures consistent performance over time. Align your choice with your device’s requirements to maximize efficiency and durability.

Tip: Evaluate your device’s voltage and current needs carefully. This ensures you select the right module for optimal performance.

FAQ

1. How do I decide between the MPM-15-12 and MPM-15-15 for my project?

Evaluate your device's power needs. If it requires 12V and higher current (up to 1.25A), choose the MPM-15-12. For applications needing 15V with moderate current (1.00A), the MPM-15-15 is better. Always check your device's specifications.

Tip: Match the module's voltage and current to your device's requirements for optimal performance.

2. Are both modules suitable for medical devices?

Yes, both modules meet IEC/EN 60601-1 medical safety standards. This ensures they are safe for use in medical equipment like patient monitors or diagnostic tools. Their compliance simplifies certification for your medical projects.

3. Can I use these modules in outdoor environments?

Both modules are durable and can handle challenging conditions. However, for outdoor use, you should protect them with enclosures rated for dust and moisture resistance. This ensures long-term reliability in harsh environments.

4. Do these modules require additional cooling systems?

No, both modules feature advanced thermal management systems. They operate efficiently without extra cooling. However, if your device generates significant heat, consider adding ventilation or heat sinks to maintain stable performance.

5. Where can I purchase the MPM-15-12 or MPM-15-15?

You can find these modules through trusted suppliers online or in stores specializing in power supply systems. Manufacturers also provide datasheets and support to help you integrate them into your projects.

Note: Check for authorized distributors to ensure you receive genuine products.

Specifications

- TypeParameter

- Factory Lead Time14 Weeks

- Mounting Type

The "Mounting Type" in electronic components refers to the method used to attach or connect a component to a circuit board or other substrate, such as through-hole, surface-mount, or panel mount.

Through Hole - Package / Case

refers to the protective housing that encases an electronic component, providing mechanical support, electrical connections, and thermal management.

4-DIP Module - Usage LevelIndustrial grade

- Operating Temperature

The operating temperature is the range of ambient temperature within which a power supply, or any other electrical equipment, operate in. This ranges from a minimum operating temperature, to a peak or maximum operating temperature, outside which, the power supply may fail.

-40°C~85°C With Derating - Series

In electronic components, the "Series" refers to a group of products that share similar characteristics, designs, or functionalities, often produced by the same manufacturer. These components within a series typically have common specifications but may vary in terms of voltage, power, or packaging to meet different application needs. The series name helps identify and differentiate between various product lines within a manufacturer's catalog.

MPM-15 (15W) - Size / Dimension

In electronic components, the parameter "Size / Dimension" refers to the physical dimensions of the component, such as its length, width, and height. These dimensions are crucial for determining how the component will fit into a circuit or system, as well as for ensuring compatibility with other components and the overall design requirements. The size of a component can also impact its performance characteristics, thermal properties, and overall functionality within a given application. Engineers and designers must carefully consider the size and dimensions of electronic components to ensure proper integration and functionality within their designs.

2.06Lx1.07W x 0.94 H 52.4mmx27.2mmx24.0mm - Part Status

Parts can have many statuses as they progress through the configuration, analysis, review, and approval stages.

Active - Moisture Sensitivity Level (MSL)

Moisture Sensitivity Level (MSL) is a standardized rating that indicates the susceptibility of electronic components, particularly semiconductors, to moisture-induced damage during storage and the soldering process, defining the allowable exposure time to ambient conditions before they require special handling or baking to prevent failures

1 (Unlimited) - TypeEnclosed

- Applications

The parameter "Applications" in electronic components refers to the specific uses or functions for which a component is designed. It encompasses various fields such as consumer electronics, industrial automation, telecommunications, automotive, and medical devices. Understanding the applications helps in selecting the right components for a particular design based on performance, reliability, and compatibility requirements. This parameter also guides manufacturers in targeting their products to relevant markets and customer needs.

Household Appliances, Medical - Number of Outputs1

- Approval Agency

The parameter "Approval Agency" in electronic components refers to the organization responsible for testing and certifying that a component meets specific safety, quality, and performance standards. These agencies evaluate products to ensure compliance with industry regulations and standards, providing assurance to manufacturers and consumers. Approval from recognized agencies can enhance a component's marketability and acceptance in various applications, particularly in sectors like automotive, aerospace, and healthcare. Common approval agencies include Underwriters Laboratories (UL), International Electrotechnical Commission (IEC), and the American National Standards Institute (ANSI).

CB, CE, cURus, EAC, TUV - Efficiency

Efficiency in electronic components refers to the ratio of useful output energy or power to the input energy or power. It is a measure of how effectively a component converts input energy into output energy without wasting any energy in the process. Higher efficiency indicates that the component is more effective in performing its intended function while minimizing energy losses. Efficiency is an important parameter in electronic components such as power supplies, amplifiers, and motors, as it directly impacts the overall performance and energy consumption of the system. Manufacturers often specify the efficiency rating of their components to help users understand how efficiently the component operates under different conditions.

86.5% - Output Power

That power available at a specified output of a device under specified conditions of operation.

15W - Line Regulation

Line regulation is the ability of a power supply to maintain a constant output voltage despite changes to the input voltage, with the output current drawn from the power supply remaining constant.

±0.3% - Load Regulation

Load regulation is the capability to maintain a constant voltage (or current) level on the output channel of a power supply despite changes in the supply's load (such as a change in resistance value connected across the supply output).

±0.5% - Features

In the context of electronic components, the term "Features" typically refers to the specific characteristics or functionalities that a particular component offers. These features can vary depending on the type of component and its intended use. For example, a microcontroller may have features such as built-in memory, analog-to-digital converters, and communication interfaces like UART or SPI.When evaluating electronic components, understanding their features is crucial in determining whether they meet the requirements of a particular project or application. Engineers and designers often look at features such as operating voltage, speed, power consumption, and communication protocols to ensure compatibility and optimal performance.In summary, the "Features" parameter in electronic components describes the unique attributes and capabilities that differentiate one component from another, helping users make informed decisions when selecting components for their electronic designs.

Universal Input - Height24mm

- RoHS Status

RoHS means “Restriction of Certain Hazardous Substances” in the “Hazardous Substances Directive” in electrical and electronic equipment.

ROHS3 Compliant

Datasheet PDF

- Datasheets :

- Environmental Information :

PIC16LF1824TIST Microcontroller Datasheet Overview

PIC16LF1824TIST Microcontroller Datasheet Overview29 February 2024106

74LS107 Dual JK Flip-Flops: Flip-Flops Datasheet pdf, Pinout and Diagram

74LS107 Dual JK Flip-Flops: Flip-Flops Datasheet pdf, Pinout and Diagram20 December 20215905

OV7670 vs OV2640 Which one is better?

OV7670 vs OV2640 Which one is better?03 March 20224017

LM301AN Operational Amplifier: 1MHZ, DIP-8 LM301AN Amplifier, Circuit and Equivalents

LM301AN Operational Amplifier: 1MHZ, DIP-8 LM301AN Amplifier, Circuit and Equivalents11 January 20224023

W25Q16JVSNIQ: Overview, Features, and Applications

W25Q16JVSNIQ: Overview, Features, and Applications28 November 20231191

![BTA16 Triacs: Features, Pinout, and Datasheet [Video&FAQ]](https://res.utmel.com/Images/Article/90a7e9a1-f4df-4f46-861a-0e4e514ca8a2.png) BTA16 Triacs: Features, Pinout, and Datasheet [Video&FAQ]

BTA16 Triacs: Features, Pinout, and Datasheet [Video&FAQ]10 January 202215669

BC558 Transistor: Pinout, Alternatives and Datasheet

BC558 Transistor: Pinout, Alternatives and Datasheet06 August 20217740

MAX80 80A 32V Socket 8.9 X 21.6mm Tin Automotive: Datasheet, cautions and specifications

MAX80 80A 32V Socket 8.9 X 21.6mm Tin Automotive: Datasheet, cautions and specifications07 January 2022222

Oregon's Semiconductor Boost: Governor Announces $240 Million Investment

Oregon's Semiconductor Boost: Governor Announces $240 Million Investment06 October 20231461

Emerging Trends in Complex Programmable Logic Devices Market 2025

Emerging Trends in Complex Programmable Logic Devices Market 202516 June 2025550

Analog-to-Digital Converters (ADCs): Decrypting Resolutions and Sampling Rates

Analog-to-Digital Converters (ADCs): Decrypting Resolutions and Sampling Rates24 February 20224272

Latest Advances in Occupancy Sensor Detection Methods

Latest Advances in Occupancy Sensor Detection Methods14 July 2025975

Semiconductor Cleaning: Processes, Methods and Reasons

Semiconductor Cleaning: Processes, Methods and Reasons20 April 202217499

What is a Semiconductor?

What is a Semiconductor?22 October 20257237

VRAM (Video RAM) Explained

VRAM (Video RAM) Explained03 June 20217600

EMI Filter: Introduction, Functions and Applications

EMI Filter: Introduction, Functions and Applications23 December 202011365

MEAN WELL USA Inc.

In Stock

Minimum: 1 Multiples: 1

Qty

Unit Price

Ext Price

1

$8.335001

$8.34

10

$7.863209

$78.63

100

$7.418121

$741.81

500

$6.998228

$3,499.11

1000

$6.602102

$6,602.10

Not the price you want? Send RFQ Now and we'll contact you ASAP.

Inquire for More Quantity