What is a Fiber Optic Connector?

Fiber Optic Connector Types Explained in Details

📅 Article Updated: This comprehensive guide has been updated with the latest 2025 standards, performance specifications, and emerging connector technologies.

Table of Contents

Ⅰ Introduction

A fiber optic connector is a detachable (removable) device that provides a connection between optical fibers. It precisely aligns the two end faces of optical fibers so that the optical energy output by the transmitting fiber can be coupled to the receiving fiber with maximum efficiency while minimizing signal loss. The connector also minimizes the impact on the optical link system due to its involvement in the transmission path. This represents the fundamental requirement of fiber optic connectors. To a significant extent, fiber optic connectors directly affect the reliability and performance of optical transmission systems. [[0]](#__0)

Ⅱ Key Features of Fiber Optic Connectors

The performance of fiber optic connectors is primarily evaluated based on optical performance characteristics. Additionally, critical factors include interchangeability, repeatability, tensile strength, temperature tolerance, and the number of mating cycles the connector can withstand. Modern 2025 standards have enhanced these requirements significantly. [[1]](#__1)

Modern fiber optic connector assembly showing precision engineering

1 Optical Performance

The optical performance requirements for fiber optic connectors focus on two fundamental parameters: insertion loss and return loss. Insertion loss represents the connection loss - the reduction in effective optical power caused by introducing the connector into the link. Lower insertion loss values are preferred, with general requirements not exceeding 0.3dB for premium connectors (improved from the previous 0.5dB standard). Return loss measures the connector's ability to suppress optical power reflection in the link, with typical values not less than 50dB for APC connectors (enhanced from 45dB in 2020). [[2]](#__2)

2 Interchangeability and Repeatability

Fiber optic connectors are universal passive devices. Connectors of the same type can generally be used in any combination and repeatedly mated multiple times. The additional losses introduced typically remain within 0.1dB (improved from 0.2dB), ensuring consistent performance across multiple connections. [[3]](#__3)

3 Tensile Strength

For high-quality fiber optic connectors, the tensile strength requirement has been increased to not less than 100N (up from 90N), ensuring robust mechanical performance in demanding applications.

4 Temperature Range

Current standards require fiber optic connectors to operate normally across an extended temperature range from -40°C to +85°C (expanded from +70°C), accommodating more diverse environmental conditions including outdoor and industrial applications.

5 Mating Cycles

Modern fiber optic connectors must withstand more than 1,500 mating cycles (increased from 1,000), with premium connectors rated for up to 10,000 cycles for high-maintenance applications. [[4]](#__4)

Ⅲ Structure of Fiber Optic Connectors

The primary purpose of fiber optic connectors is to achieve precise optical fiber splicing. While numerous types of fiber optic connectors are widely used in fiber optic communication systems, they share fundamental structural similarities. Most connectors utilize high-precision components consisting of ferrules and coupling mechanisms to achieve optimal fiber alignment.

Fiber optic connector alignment principle showing precision coupling

In this alignment method, the optical fiber is inserted and secured within the ferrule, with the ferrule end face polished to achieve precise alignment within the coupling sleeve. The ferrule components are manufactured from metal, ceramic, or advanced polymer materials. The mating end of the ferrule must be precisely polished, while the cable end typically incorporates strain relief components to support the optical fiber and manage mechanical stress.

The coupling sleeve is typically constructed from ceramic, bronze, or advanced composite materials, often equipped with metal or plastic flanges to facilitate connector installation and securing. To achieve optimal fiber alignment accuracy, both ferrule and coupling sleeve manufacturing tolerances are extremely tight, typically within ±1 micrometer. [[6]](#__6)

Key Components of All Fiber Connectors:

Ferrule: Houses and aligns the optical fiber with precision-drilled center hole

Connector Body: Protective housing that secures the ferrule and cable assembly

Cable Assembly: Includes strain relief and protective boot

Coupling Mechanism: Alignment sleeve or adapter for mating connectors

Ⅳ Types of Fiber Optic Connectors

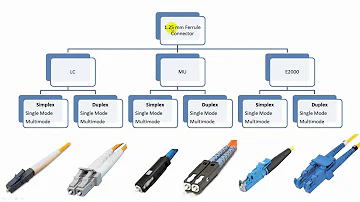

Fiber optic connectors can be categorized by transmission medium (single-mode vs. multimode), structural design, end-face geometry, and fiber count. According to 2025 industry standards, connectors are classified into common silicon-based fiber types and specialized plastic optical fiber (POF) connectors. Structurally, they include FC, SC, ST, LC, MPO/MTP, and emerging high-density variants. [[1]](#__1)

| Connector Type | Ferrule Size | Typical Loss (dB) | Return Loss (dB) | Primary Application |

|---|---|---|---|---|

| FC | 2.5mm | ≤0.3 | ≥50 (APC) | Test equipment, single-mode |

| SC | 2.5mm | ≤0.3 | ≥50 (APC) | Telecom, data centers |

| LC | 1.25mm | ≤0.25 | ≥55 (APC) | High-density applications |

| MPO/MTP | Multi-fiber | ≤0.35 | ≥20 | Data centers, parallel optics |

1 FC Connector

The FC (Ferrule Connector) fiber optic connector was originally developed by NTT (Nippon Telegraph and Telephone). The designation indicates external reinforcement using a metal sleeve with a threaded coupling mechanism. Early FC connectors featured flat contact (FC) ceramic ferrule end faces. While structurally simple and easy to manufacture, these connectors were sensitive to contamination and prone to Fresnel reflection, limiting return loss performance. Modern FC connectors utilize Physical Contact (PC) or Angled Physical Contact (APC) polishing, significantly improving both insertion loss and return loss characteristics. Current FC connectors achieve insertion losses below 0.2dB and return losses exceeding 55dB for APC variants. [[0]](#__0)

FC fiber optic connector featuring threaded coupling mechanism

2 SC Connector

The SC (Subscriber Connector) was developed by NTT featuring a rectangular outer shell. The ferrule and coupling sleeve dimensions match FC-type connectors exactly, with end faces typically utilizing PC or APC polishing methods. The fastening mechanism employs a push-pull design without rotation requirements. SC connectors offer cost-effective solutions with easy mating/unmating, minimal insertion loss variation, high compressive strength, and excellent installation density. They remain the standard for many telecommunications applications and are widely specified in building infrastructure. [[2]](#__2)

SC fiber optic connector with push-pull coupling mechanism

3 ST Connector

The ST (Straight Tip) connector, developed by AT&T, features a bayonet coupling mechanism similar to BNC electrical connectors. It uses a 2.5mm ceramic ferrule and spring-loaded design for consistent connection pressure. ST connectors were widely used in early fiber optic networks, particularly for multimode applications, but have largely been superseded by LC and SC connectors in new installations. However, they remain common in legacy systems and some industrial applications. [[3]](#__3)

4 MT-RJ Connector

The MT-RJ (Mechanical Transfer Registered Jack) evolved from NTT's MT connector technology, incorporating an RJ-45-style latch mechanism familiar to network technicians. It features dual-fiber (duplex) configuration with 0.75mm fiber spacing, aligned using precision guide pins. MT-RJ connectors are optimized for data transmission applications and offer space-efficient duplex connectivity. While popular in early 2000s data center applications, they have been largely replaced by LC duplex connectors due to superior performance and smaller form factor. [[4]](#__4)

5 LC Connector

The LC (Lucent Connector) was developed by Bell Labs (Lucent Technologies) and features an RJ-style latch mechanism for easy operation. Utilizing a 1.25mm ferrule - half the size of standard SC/FC connectors - LC connectors enable significantly higher port density in fiber distribution panels. The small form factor (SFF) design has made LC connectors dominant in single-mode applications and increasingly popular in multimode networks. Current LC connectors achieve insertion losses below 0.15dB and return losses exceeding 60dB for APC variants, making them ideal for high-performance applications including 400G and 800G optical transceivers. [[2]](#__2)

LC connector demonstrating compact 1.25mm ferrule design

6 MU Connector

The MU (Miniature Unit Coupling) connector represents NTT's smallest single-fiber connector design, based on successful SC connector technology. Using a 1.25mm ferrule with self-retaining mechanism, MU connectors enable extremely high-density installations. The MU family includes various configurations: MU-A series for cable connections, MU-B series backplane connectors with self-retaining mechanisms, and MU-SR simplified socket variants for LD/PD module connections. With increasing demand for higher bandwidth density and widespread DWDM deployment, MU-type connectors continue to find applications in specialized high-density environments.

7 MPO/MTP Connector

MPO (Multi-fiber Push-On) and MTP (Multi-fiber Termination Push-on) connectors represent the current standard for high-density parallel fiber applications. These connectors can accommodate 8, 12, 16, 24, or even 72 fibers in a single connector interface. MTP is the premium version with enhanced specifications including better endface geometry and improved mechanical precision. These connectors are essential for modern data center applications, supporting 40G, 100G, 400G, and 800G parallel optical interfaces. Current specifications achieve insertion losses below 0.35dB per fiber and support over 5,000 mating cycles. [[1]](#__1)

8 Emerging Connector Types

Several new connector technologies have emerged to address evolving market demands:

SN (Small Form Factor) Connectors: Even smaller than LC, designed for ultra-high-density applications

MDC (Multi-Directional Connector): Enables flexible routing in tight spaces

Expanded Beam Connectors: Utilize lens systems for reduced sensitivity to contamination

Harsh Environment Connectors: Ruggedized designs for military, aerospace, and industrial applications

🔄 2025 Updates and Industry Developments

Enhanced Performance Standards

The fiber optic industry has implemented stricter performance requirements in 2025, driven by increasing demand for higher bandwidth and more reliable connections. Key improvements include:

Reduced insertion loss requirements (now ≤0.25dB for premium connectors)

Enhanced return loss specifications (≥55dB for APC connectors)

Extended temperature operating ranges (-40°C to +85°C)

Increased mating cycle requirements (up to 10,000 cycles for premium applications)

Market Trends and Adoption

According to 2025 industry analysis, LC connectors have achieved dominant market position, representing over 60% of new single-mode installations. MPO/MTP connectors continue rapid growth in data center applications, driven by 400G and 800G optical module deployment. SC connectors remain prevalent in telecommunications infrastructure, while FC connectors maintain their position in test and measurement applications. [[1]](#__1)

Emerging Technologies

New developments in 2025 include:

AI-Assisted Connector Manufacturing: Improving precision and reducing defect rates

Advanced Materials: New ceramic and polymer formulations for enhanced durability

Smart Connectors: Integration of monitoring capabilities for predictive maintenance

Sustainable Manufacturing: Eco-friendly materials and recycling programs

Future Outlook

The fiber optic connector market continues evolving toward higher density, improved performance, and enhanced reliability. Key focus areas include supporting next-generation 1.6T and 3.2T optical interfaces, developing connectors for space-based applications, and creating more sustainable manufacturing processes. The industry expects continued growth driven by 5G deployment, edge computing expansion, and increasing demand for high-speed data transmission. [[8]](#__8)

Sources:

[[0]](#__0): FS.com - Comprehensive Fiber Connector Guide

[[1]](#__1): Delco Cables - 2025 Fiber Connector Types

[[2]](#__2): Asterfusion - LC vs SC vs FC vs MPO Comparison

[[3]](#__3): Cables and Kits - Fiber Optic Connector Applications

[[4]](#__4): ShowMeCables - Connector Types and Configurations

[[6]](#__6): The Fiber Optic Association - Technical Specifications

[[8]](#__8): JM Test Systems - Professional Connector Selection Guide

Last Updated: October 2025 | Next Review: April 2026

What connectors are used for fiber optics?

*ST Connectors: Slotted bayonet type Connector with long ferrule. *FC Connectors: Screw on type connector. *SC Connectors: Push/pull connector that can also be used with Duplex fiber constuction. *LC Connectors: Much like the ST connector but with a Ferrule that is half the size.

How many types of fiber optic connectors are there?

100 different types In all, about 100 different types of fiber optic connectors have been introduced to the market.

What is the standard fiber optic connector?

Common 2.5mm Connectors SC, FC and ST fiber optic connectors all feature a 2.5mm ferrule size and can therefore be mixed and matched using special hybrid adapters. Developed by Nippon Telegraph and Telephone (NTT), the SC connector is easily recognized by its square shape.

What are the 4 network fiber connectors?

All fiber optic connectors have four basic components, which are the ferrule, connector body, cable, and coupling device. For multimode networks such as those used in buildings and campuses, the ST is the most common fiber optic connector.

What are the 2 types of fiber optic cable?

There are two primary types of fibre – multimode and singlemode.

The Introduction to USB Type-C Pin Signal and PCB LayoutUTMEL03 December 202125158

The Introduction to USB Type-C Pin Signal and PCB LayoutUTMEL03 December 202125158Hello everyone. Welcome to the new post today. USB Type-C is a smaller-volume USB interface standard than Type-A and Type-B. It can be used on a PC (master device) as well as external devices (slave devices, such as mobile phones).

Read More Everything You Need to Know about ConnectorsUTMEL07 September 20217628

Everything You Need to Know about ConnectorsUTMEL07 September 20217628Electrical connectors, as key components for current or signal connections, are also an important part of the industrial system. Connectors can be as huge as airplanes and rockets or as small as mobile phones and televisions, forming bridges between circuits or other components and serving as electric current or signal links.

Read More Network Interface Card: Types, Functions and Buying GuideUTMEL17 August 20219838

Network Interface Card: Types, Functions and Buying GuideUTMEL17 August 20219838Network Interface Card (NIC, also known as a network interface controller) is one of the most basic components in the local area network. It is the hardware device connecting the computer and the network. Whether it is a twisted pair connection, a coaxial cable connection, or an optical fiber connection, data communication must be realized with the help of a network interface card.

Read More What is Universal Serial Bus (USB)?UTMEL19 January 202611539

What is Universal Serial Bus (USB)?UTMEL19 January 202611539Universal Serial Bus (USB) is a serial bus standard and a technical specification for input and output interfaces. It is widely used in information communication devices. The latest generation is USB4, and its transmission speed is 40Gbit/s, the three-stage voltage is 5V/12V/20V, the maximum power supply is 100W.

Read More Classification and Selection of Industrial ConnectorsUTMEL11 February 20225327

Classification and Selection of Industrial ConnectorsUTMEL11 February 20225327This article mainly introduces a very important component-connector in the modern industrial system, including its definition, classification, and selection.

Read More

Subscribe to Utmel !

![9668TREK48E]() 9668TREK48E

9668TREK48EAdvantech Corp

![ACP-4010BP-00BE]() ACP-4010BP-00BE

ACP-4010BP-00BEAdvantech Corp

![ACP-4340BP-00XE]() ACP-4340BP-00XE

ACP-4340BP-00XEAdvantech Corp

![UPOS-3150-RHW0E]() UPOS-3150-RHW0E

UPOS-3150-RHW0EAdvantech Corp

![AIMB-T12251W-00Y0E]() AIMB-T12251W-00Y0E

AIMB-T12251W-00Y0EAdvantech Corp

![IPC-6608BP-00E]() IPC-6608BP-00E

IPC-6608BP-00EAdvantech Corp

![ACP-4000BP-00CE]() ACP-4000BP-00CE

ACP-4000BP-00CEAdvantech Corp

![96ND2.4T-SS-SG10E]() 96ND2.4T-SS-SG10E

96ND2.4T-SS-SG10EAdvantech Corp

![PCE-3B04-03A1E]() PCE-3B04-03A1E

PCE-3B04-03A1EAdvantech Corp

![IPC-610BP-00LBE]() IPC-610BP-00LBE

IPC-610BP-00LBEAdvantech Corp