Introduction to Mass Air Flow Sensor

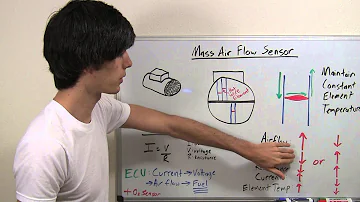

How Mass AIr flow Sensor Works?

Catalog

Ⅰ Introduction

Mass air flow sensor is one of the important sensors of EFI engines. It converts the inhaled air flow into an electric signal and sends it to the electronic control unit (ECU). As one of the basic signals for determining fuel injection, it is a sensor that measures the air flow into the engine.

Mass air flow sensor

In order to obtain the best concentration of the mixture under various operating conditions, the electronically controlled gasoline injection engine must accurately measure the amount of air sucked into the engine at each moment, which is the main basis for the ECU to calculate (control) the amount of fuel injection. If the mass air flow sensor or the circuit fails, the ECU cannot obtain the correct intake signal, and the fuel injection quantity cannot be controlled normally, which will cause the mixture to be too rich or too lean, and the engine will not operate normally. There are many types of mass air flow sensors for electronically controlled gasoline injection systems. Common mass air flow sensors can be divided into blade (wing plate) type, measuring core type, hot wire type, hot film type, Karman scroll type, etc. according to their structure.

Ⅱ Structure and principle

On the electronically controlled fuel injection device, the sensor measures the amount of air taken by the engine. That is, the mass air flow sensor is one of the important components that determine the control accuracy of the system. When the control accuracy of the air-fuel ratio (A/F) of the air and mixed gas sucked by the engine is specified to be ±1.0, the allowable error of the system is ±6[%]~7[%], and this allowable error is allocated to the system. The allowable error of the mass air flow sensor is ±2[%]~3[%].

hot wire mass air flow sensor

The ratio max/min between the maximum and minimum air flow intake of a gasoline engine is 40-50 in a natural intake system, and 60-70 in a supercharged system. In this range, the air flow sensor should be able to maintain a measurement accuracy of ±2~3[%]. The mass air flow sensor used in the electronic control fuel injection device should not only maintain the measurement accuracy over a wide measurement range, but also have excellent measurement response and can be measured. For pulsating air flow, the output signal processing should be simple.

According to the different characteristics of the mass air flow sensor, the fuel control system is divided into L-type control for direct measurement of intake air volume and D-type control for indirect measurement of intake air volume. The microcomputer ROM in the D-type control mode stores in advance the intake air volume under various conditions based on the engine speed and the pressure in the intake pipe. The microcomputer is based on the measured operation of the intake pressure and rotation speed in the state, refer to the intake volume memorized by ROM, can calculate the fuel volume. The air flow meter used for L-type control is basically the same as the general industrial flow sensor, but it can adapt to the harsh environment of the car and the sudden change in flow rate that occurs during throttle and it can meet the requirement for high-precision detection in the uneven airflow caused by the shape of the intake manifold before and after the sensor.

hot film mass air flow sensor

The original electronic fuel injection control system did not use a microcomputer. It was an analog circuit. At that time, a valve-type mass air flow sensor was used, but as a microcomputer was used to control fuel injection, several other mass air flow sensors appeared.

The structure of the valve type mass air flow sensor

The valve type mass air flow sensor is installed on the gasoline engine and is installed between the air filter and the throttle. Its function is to detect the intake air volume of the engine, and convert the detection result into an electrical signal, which is then input into the computer. The sensor is composed of an air flow meter and a potentiometer.

First look at the working process of the mass air flow sensor. The air sucked by the air cleaner rushes to the valve, and the valve turns to a position where the intake air volume is balanced with the return spring and stops, that is, the opening of the valve is proportional to the air intake volume. A potentiometer is also installed on the rotating shaft of the valve. The sliding arm of the potentiometer rotates synchronously with the valve. The voltage drop of the sliding resistance is used to convert the opening of the measuring piece into an electrical signal, which is then input to the control circuit.

Ⅲ Karman scroll mass air flow sensor

In order to overcome the shortcomings of the valve type mass air flow sensor, that is, under the premise of ensuring the measurement accuracy, expanding the measurement range, and eliminating the sliding contact, a small and lightweight mass air flow sensor has been developed, namely the Kaman vortex mass air flow sensor. The Karman vortex is a physical phenomenon. The detection method of the vortex and the electronic control circuit have nothing to do with the detection accuracy. The air passage area and the size change of the vortex generating column determine the detection accuracy. And because the output of this sensor is an electronic signal (frequency), when inputting a signal to the control circuit of the system, the AD converter can be omitted. Therefore, from an essential point of view, the Karman vortex mass air flow sensor is a signal suitable for microcomputer processing. This sensor has the following three advantages: high test accuracy, can output linear signals, and simple signal processing; long-term use, performance will not change. Because it detects volume flow, it does not require correction of temperature and atmospheric pressure.

When a Karman vortex is generated, it follows the change of speed and pressure. The basic principle of flow detection is to use the change of speed. The signal is square wave, digital signal. The more air intake, the higher the frequency of the Kaman vortex, and the higher the frequency of the output signal of the mass air flow sensor.

The temperature and pressure compensation mass air flow sensor is mainly used for the flow measurement of industrial pipeline fluids, such as gas, liquid, steam and other media. It is characterized by small pressure loss, large measuring range, and high accuracy. It is hardly affected by fluid density, pressure, temperature, viscosity and other parameters when measuring volume flow under working conditions. There are no movable mechanical parts, so the reliability is high and the maintenance is small. The instrument parameters can be stable for a long time. This instrument adopts piezoelectric stress sensor, which has high reliability and can work in the working temperature range of -10℃~+300℃. There are analog standard signals and digital pulse signal output, which is easy to use with digital systems such as computers. It is a relatively advanced and ideal flow.

The biggest advantage of the mass air flow sensor is that the meter coefficient is not affected by the physical properties of the measuring medium, and can be extended from a typical medium to other mediums. However, due to the large difference in the flow rate range of liquid and gas, the frequency range is also very different. In the amplifier circuit that processes the vortex signal, the passband of the filter is different, and the circuit parameters are also different. Therefore, the same circuit parameter cannot be used to measure different media.

Ⅳ Measuring range

The meter passage and measuring range of the mass air flow sensor are shown in the following table:

Detection principle

The overhead wires in the wild will whine when they are blown by the wind. The higher the wind speed, the higher the sound frequency. This is caused by the formation of a vortex after the airflow flows through the wire. This phenomenon occurs in fluids such as liquids and gases, which can be used to make a vortex flow sensor. Two rows of vortices are formed after the pillars are installed in the pipe, and the flow rate can be measured according to the frequency of the vortices. Because the vortex is in two parallel rows and alternates from left to right, similar to the street lights on both sides of the street, it is called the vortex street. Because this phenomenon was first discovered by Kaman, it is also called Kaman vortex street ultrasonic Kaman vortex mass air flow sensor.

The ultrasonic mass air flow sensor has two intake channels, the main channel and the bypass channel, and the detection of the intake flow. Part is set on the main channel, and the purpose of setting the bypass channel is to adjust the flow rate of the main channel so that the detection characteristics of the main channel are in an ideal state. That is to say, for engines with different displacements, by changing the size of the mass air flow sensor channel section, it is possible to cover multiple engines with one specification of mass air flow sensor. The triangular column on the main channel and several vortex amplifying plates constitute the Kaman vortex generator. On both sides of the place where the Karman vortex is generated, the ultrasonic transmitter and the ultrasonic receiver belonging to the electronic detection device are arranged oppositely. These two components can also be classified into the sensor.

The electrical signal generated by the two electronic sensors is passed through the air. The control circuit (hybrid integrated circuit) of the flow sensor is shaped and amplified into an ideal waveform, and then input into the microcomputer. In order to inspect the vortex with ultrasound, sound-absorbing materials are glued on the inner wall of the vortex channel to prevent irregular reflection of the ultrasonic waves.

Ⅴ Frequently asked questions

1. What are the symptoms of a bad mass air flow sensor?

Symptoms of a Faulty Mass Air Flow Sensor

The engine is very hard to start or turn over.

The engine stalls shortly after starting.

The engine hesitates or drags while under load or idle.

Hesitation and jerking during acceleration.

The engine hiccups.

Excessively rich or lean idling.

2. Can you drive with a bad mass air flow sensor?

You can drive your vehicle with a bad mass air flow sensor for a while, but it is not advisable to continue doing so for a long time even if your car can still run and that is because, Ignoring your car MAF sensor problem can escalate beyond just the Mass air flow sensor problem to a more severe engine problem that might even require getting a new engine.

3. What does a mass airflow sensor do?

A mass (air) flow sensor (MAF) is a sensor used to determine the mass flow rate of air entering a fuel-injected internal combustion engine. The air mass information is necessary for the engine control unit (ECU) to balance and deliver the correct fuel mass to the engine.

4. How much does it cost to replace a mass air flow sensor?

To get your mass air flow sensor replaced, you will pay about $300, on average. The labor should cost you around $60, while parts are about $240. The prices vary based on where you go for servicing and what kind of car you have.

5. Why would a car run better with the mass air flow sensor unplugged?

Because either the sensor is reporting incorrect air amount and or air temperature to the ECU. By disconnecting the sensor the ECU switches to limp mode and the car may idle better . Some MAF sensor wires can be cleaned and some cannot as the wires are not easily accessible.

6. Can a dirty mass air flow sensor cause misfire?

Even a dirty MAF sensor can cause a lean code and/or misfire to occur. The engine may be stalling because it isn't getting enough throttle opening. The cause is often a problem in the idle air control system. The first thing to check is the intake vacuum with a vacuum gauge.

7. How long do mass air flow sensors last?

Routine maintenance and air filter replacement can extend the life of your MAF sensor and ensure it continues to work correctly. While the exact timing varies based on where and how much you drive, a good rule to follow is every 10,000 to 12,000 miles.

8. Is it easy to replace MAF sensor?

Mass air flow sensor replacement is very easy to accomplish. One only needs the correct tools and materials for the job. If all goes well, you can have a new MAF sensor in under 15 minutes.

9. Can a mass airflow sensor be cleaned?

We recommend that you clean the MAF sensor every time you change your air filter. Carefully remove the sensor from the air duct and disconnect the electrical connector. Spray 10 to 15 spurts of the mass air flower cleaner onto the wire or plate. Don't scrub the parts; you may break the wire or damage the plate.

10. What makes a MAF sensor go bad?

The sensor element could get contaminated or damaged. For example, in some Mazda Skyactiv engines, a failed mass air flow sensor could cause the engine to crank but not to start. An improperly installed or collapsed air filter can cause the air flow sensor to fail sooner.

Related articles:

The Key Role of Electronic Components in IoT DevicesUTMEL01 September 20235083

The Key Role of Electronic Components in IoT DevicesUTMEL01 September 20235083The article discusses the pivotal role of electronic components in Internet of Things (IoT) devices. IoT devices work by capturing real-world data using sensors, processing it through a microcontroller, and then sending it to the cloud for further analysis.

Read More How to Identify the Perfect Proximity Sensor for Your ApplicationUTMEL19 July 20251000

How to Identify the Perfect Proximity Sensor for Your ApplicationUTMEL19 July 20251000Find the best proximity sensors for your project by evaluating material, sensing range, environment, and system needs to ensure optimal performance and reliability.

Read More Trusted Vibration Sensors for Homeowners and Industry ProfessionalsUTMEL17 July 2025688

Trusted Vibration Sensors for Homeowners and Industry ProfessionalsUTMEL17 July 2025688Compare top vibration sensors for home and industrial use. Find trusted options for security, predictive maintenance, and equipment protection.

Read More Wiring and Mounting Photoelectric Sensors in 2025UTMEL15 July 2025898

Wiring and Mounting Photoelectric Sensors in 2025UTMEL15 July 2025898Wire and mount photoelectric sensors in 2025 with step-by-step safety, wiring, and alignment tips for reliable installation and optimal sensor performance.

Read More Essential Tips for Picking the Best Gas SensorUTMEL15 July 20252051

Essential Tips for Picking the Best Gas SensorUTMEL15 July 20252051Find out how to select gas sensors by matching target gases, environment, and compliance needs for reliable and accurate gas detection in any setting.

Read More

Subscribe to Utmel !

![EPM80CS154]() EPM80CS154

EPM80CS154Menda

![ES80BVF020]() ES80BVF020

ES80BVF020Menda

![04643]() 04643

04643Schneider

![5060-$]() 5060-$

5060-$Brady Corporation

![5000-4]() 5000-4

5000-4Brady Corporation

![5000-3]() 5000-3

5000-3Brady Corporation

![60506]() 60506

60506Brady Corporation

![43754]() 43754

43754Brady Corporation

![ETM80CS152]() ETM80CS152

ETM80CS152Menda

![ES60CH010]() ES60CH010

ES60CH010Menda