How Proper Thermal Management Extends the Life of Your Electronics

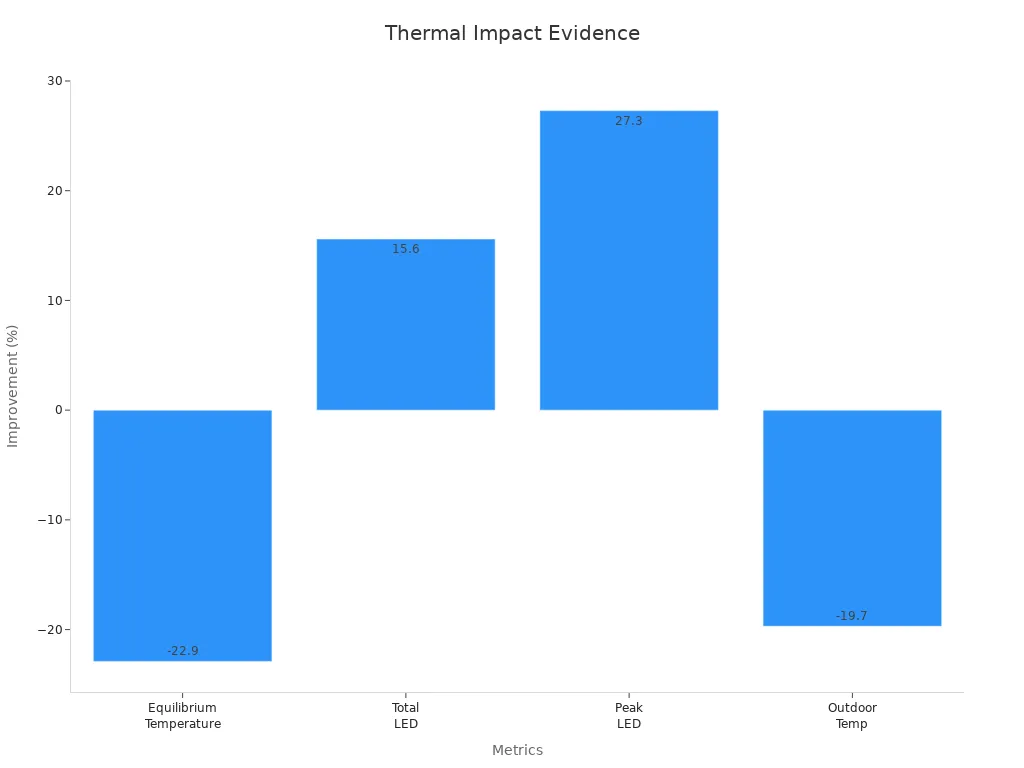

Proper thermal management plays a critical role in preventing overheating and device failure. Excess heat can shorten component lifespan and cause unexpected shutdowns. Devices such as smartphones, laptops, and battery-powered tools all depend on stable temperature control to maintain device performance. Research shows that effective thermal management lowers equilibrium temperature by nearly 23%, boosts LED emission intensity, and keeps outdoor devices cooler.

| Metric | Device with USRI | Control Device | Improvement (%) |

|---|---|---|---|

| Equilibrium Temperature (°C) | 43.7 | 56.7 | -22.9 |

| Total LED Emission Intensity | Baseline + 15.6% | Baseline | +15.6 |

| Outdoor Device Temperature (°C) | 33.8 | 42.1 | -19.7 |

Devices with advanced thermal management maintain steady temperature even under stress, leading to greater reliability and longer service life.

Why Thermal Management Matters

Component Damage

Electronic devices rely on precise control of temperature to function correctly. When heat builds up inside a device, sensitive components such as chips, batteries, and connectors face stress. Overheating can cause materials to expand and contract, leading to cracks or broken solder joints. This process, known as thermal cycling fatigue, often results in permanent damage.

Research shows that temperature is the leading cause of electronic device failures. The table below highlights the main causes:

| Cause of Failure | Percentage of Failures |

|---|---|

| Temperature | Over 55% |

| Vibration | About 45% |

| Humidity | 19% |

| Dust | 8% |

More than half of all failures in electronics come from poor thermal management. When devices operate above their recommended temperature range, chips can burn out and batteries degrade faster. These failures not only affect performance but also increase the risk of sudden shutdowns or permanent loss of function.

Tip: Keeping devices cool helps prevent costly repairs and extends their usable life.

Lifespan & Reliability

Thermal management plays a key role in ensuring the performance and longevity of electronics. Devices that maintain optimal performance levels often use advanced cooling methods to keep internal temperatures stable. High temperatures speed up battery wear, reduce charging efficiency, and can even trigger dangerous events like thermal runaway in batteries.

Studies reveal several benefits of effective thermal management:

It prevents overheating, which can cause system failure and reduce device life.

It slows battery degradation, helping batteries last longer and perform better.

It improves charging efficiency and safety, especially in electric vehicles.

It uses techniques like conduction, convection, and both active and passive cooling to boost reliability.

Manufacturers design modern electronics with these strategies in mind. They use heat sinks, fans, and smart battery management systems to keep temperature under control. As a result, devices stay reliable and safe for longer periods. Good thermal management ensures that users experience fewer breakdowns and enjoy consistent performance throughout the device’s life.

Risks of Poor Thermal Management

Performance Loss

Heat is a constant byproduct of electronic operation. Devices convert almost all electrical power into heat, which must be managed. When thermal challenges go unchecked, performance drops quickly. High temperatures cause molecular vibrations in materials, leading to expansion and stress. This stress can deform components and cause them to fail early. In data centers, operators measure heat output by tracking power input. If cooling systems cannot keep up, servers slow down or shut off to prevent damage. Studies show that electric vehicles lose up to 20% of their range when exposed to sustained high temperatures, such as 90°F. These thermal management challenges affect not only large systems but also everyday devices like laptops and smartphones. Users may notice slower speeds, unexpected shutdowns, or reduced battery life when devices overheat.

Safety Hazards

Poor thermal management can create serious safety risks. Overheating in lithium-ion batteries sometimes leads to thermal runaway, a rapid and uncontrollable rise in temperature. This process can cause fires, explosions, and the release of toxic gases. Case studies document incidents where batteries caught fire due to overcharging, physical damage, or exposure to excessive heat. The OVHcloud Strasbourg fire in March 2021 highlights the dangers in data centers. Overheating equipment and insufficient cooling contributed to the fire, which destroyed an entire building and caused major data loss. Electrical failures, faulty wiring, and poor maintenance often make these risks worse. Fire prevention systems and early detection are essential to protect both property and people.

Note: Proper storage, handling, and charging of batteries help prevent dangerous incidents. Data centers rely on strict safety protocols to reduce fire hazards.

Costly Repairs

Ignoring thermal challenges leads to expensive repairs and downtime. When devices overheat, components like chips, connectors, and batteries degrade faster. In data centers, a single overheating event can damage hundreds of servers, resulting in lost data and high replacement costs. The OVHcloud incident caused significant operational downtime and irreversible data loss for many businesses. For consumers, overheating can mean replacing a phone battery or even the entire device. Regular maintenance and effective cooling systems help avoid these costly outcomes. Addressing thermal management challenges early saves money and keeps devices running smoothly.

How Effective Thermal Management Works

Heat Transfer Basics

Every electronic device generates heat during operation. Heat management starts with understanding how heat moves from one place to another. Three main processes drive this movement: conduction, convection, and radiation. Conduction happens when heat travels through solid materials, such as from a processor to a heat sink. Convection moves heat away by using air or liquid, often with the help of fans or pumps. Radiation sends heat out as energy waves, but this plays a smaller role in most electronics.

Engineers use these principles to design cooling solutions that keep temperature under control. Good heat dissipation protects sensitive parts and improves energy efficiency. When devices stay cool, they work better and last longer. Temperature control also helps prevent sudden shutdowns and keeps performance steady.

Cooling Methods

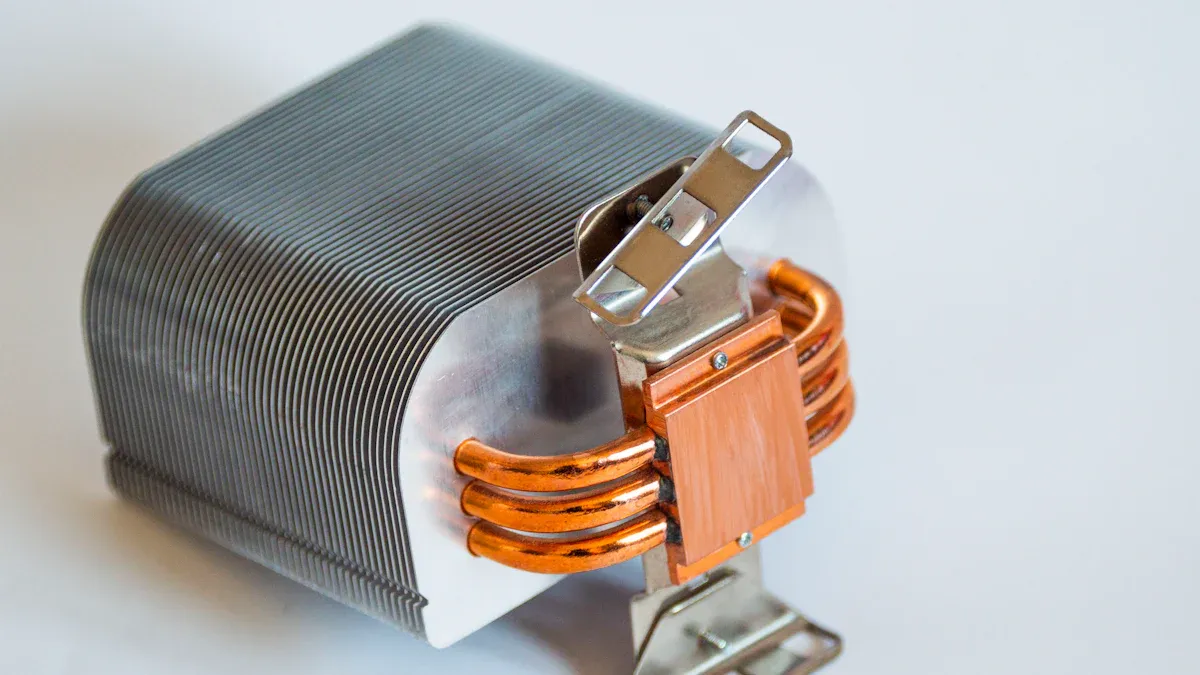

Thermal management applications use a range of cooling solutions to handle heat. Some devices rely on passive methods, such as heat sinks made from copper or aluminum. These materials pull heat away from hot components and spread it out. Other devices use active cooling methods, like fans or pumps, to move air or liquid and carry heat away faster.

The table below shows how different engineering principles support effective thermal management:

| Engineering Principle | Thermal Management Technique | Explanation and Effectiveness |

|---|---|---|

| Conduction | Heat sinks | Use materials with high thermal conductivity (e.g., copper, aluminum) and increased surface area (fins) to transfer heat rapidly from components to air. |

| Convection (free and forced) | Forced air cooling (fans) | Fans increase fluid velocity, enhancing heat transfer by maintaining a larger temperature gradient and replacing warmed air quickly. |

| Phase change and capillary action | Heat pipes | Utilize evaporation and condensation of a working fluid inside a sealed tube to transfer heat efficiently with minimal temperature difference. |

| Thermal interface materials | Thermal grease and interface pads | Improve thermal contact between components and heat sinks, reducing thermal resistance and enhancing heat flow. |

| Material science | Advanced materials (synthetic diamond, boron arsenide) | High thermal conductivity materials researched to improve cooling performance beyond traditional metals. |

| Computational fluid dynamics (CFD) | Thermal simulation | Enables prediction and optimization of temperature and airflow in designs, allowing early detection and correction of thermal issues. |

Many modern devices combine several cooling solutions for the best results. Good heat management not only improves energy efficiency but also extends device life. When engineers design systems with proper temperature control, electronics stay safe and reliable.

Tip: Regular cleaning of vents and fans helps maintain effective heat dissipation and prevents overheating.

Battery Engineering & Management

Battery Management Systems

Battery engineering has advanced rapidly to address the challenges of heat and safety in li-ion batteries. Battery management systems (BMS) play a central role in modern battery-powered devices. These systems use hardware components such as sensors to monitor temperature, voltage, and current. Advanced safety circuits prevent overcharging, over-discharging, and overheating. Communication devices allow the BMS to interact with other systems in electric vehicles and energy storage units.

Software in battery management systems controls hardware operation and performs real-time fault detection. Algorithms estimate the state of charge (SOC) and state of health (SOH) for each cell. BMS units balance cells, detect faults, and optimize charging and discharging. They help prevent hazardous conditions like short circuits and thermal runaway. Safe BMS design requires careful system architecture, sensor placement, and rigorous testing. These smart thermal management systems ensure battery safety, reliability, and longer service life.

Tip: A well-designed BMS can extend battery performance and reduce the risk of sudden failures.

Battery Safety & Lifespan

Battery engineering focuses on preventing thermal runaway and improving battery performance. Research shows that mechanical abuse, internal short circuits, and overcharging can trigger dangerous heat buildup in li-ion batteries. Engineers use several methods to suppress these risks:

| Aspect | Description | Supporting References |

|---|---|---|

| Suppression Methods | Insulation, enhanced heat dissipation, flame retardant additives, epoxy resin plates between battery packs | Shahid et al. (2022), Hu et al. (2024) |

| Structural Design | Epoxy resin plates slow heat transfer and reduce damage from thermal runaway | Yang et al. (2023) |

| Safety Strategies | Heat insulation devices, current interrupting devices, safety vents, fire suppression | Sun et al. (2024), Wang et al. (2018) |

Thermal management systems, including liquid cooling and phase change materials, help maintain safe temperatures in li-ion batteries. These systems absorb and remove excess heat, preventing temperature spikes and reducing thermal stress. Uniform temperature control lowers the risk of thermal runaway and extends battery lifespan. Proper battery engineering and thermal management systems keep battery performance high and ensure safety in electric vehicles and portable devices.

Thermal Management Solutions

Selecting the right thermal management solutions can make a significant difference in the performance and longevity of electronic devices. Engineers and users must understand the options available to keep devices cool and reliable. These solutions fall into two main categories: passive and active. Each approach offers unique benefits and challenges.

Passive Solutions

Passive thermal management solutions use natural processes to move heat away from sensitive components. These methods do not require extra energy input, making them both cost-effective and energy efficient. Devices such as smartphones, laptops, and desktops often rely on passive cooling techniques to maintain safe operating temperatures.

Common passive solutions include:

Heat sinks made from materials like copper or aluminum

Heat spreaders that distribute heat across a larger surface area

Thermal interface materials that improve contact between components and heat sinks

Heat pipes that transfer heat using phase change and capillary action

Research supports several actionable strategies for passive cooling:

Use natural ventilation, such as cross breezes, to increase airflow and lower device temperature.

Incorporate reflective surfaces to reduce heat absorption.

Employ shading devices to block direct sunlight from reaching electronics.

Utilize water evaporation methods to cool air naturally around devices.

Tip: Regularly clean vents and remove dust from heat sinks to keep passive cooling effective.

Field studies and engineering simulations show that passive cooling provides reliable thermal management for many devices. For example, virtual testing of heat sink designs and printed circuit boards helps engineers optimize performance without building physical prototypes. These passive solutions reduce energy consumption and improve device comfort, especially in environments where mechanical cooling is not practical.

Active Solutions

Active thermal management solutions use external devices to enhance heat removal. These systems include fans, blowers, liquid cooling, and thermoelectric coolers. Active cooling increases fluid flow, which helps carry heat away from hot components more quickly than passive methods.

Active solutions offer several advantages:

Rapid heat removal during high-performance tasks

Greater control over device temperature

Ability to cool high-power components in desktops, servers, and electric vehicles

However, active cooling comes with trade-offs. These systems require additional energy, which can reduce overall energy efficiency. They also increase system complexity and cost. Expert reviews highlight that while active thermal management can extend the life of power modules and batteries, it may lower efficiency due to higher energy use. Engineers must balance the benefits of improved reliability and longevity against the increased operational costs.

A comprehensive comparison between passive and active solutions shows that passive cooling is ideal for low-power devices and environments where energy savings matter most. Active cooling becomes necessary for high-performance systems that generate more heat than passive methods can handle.

| Solution Type | Examples | Energy Use | Cost | Best For |

|---|---|---|---|---|

| Passive | Heat sinks, heat pipes | Low | Low | Phones, tablets, small laptops |

| Active | Fans, liquid cooling | High | Moderate | Gaming PCs, servers, EVs |

Note: Use engineering simulation software to test and compare cooling designs before choosing a solution.

Device-Specific Tips

Different devices require tailored thermal management strategies. Users and engineers can apply the following tips to maximize device lifespan and performance:

Smartphones and Tablets

Avoid direct sunlight and hot environments.

Remove cases during heavy use or charging to improve heat dissipation.

Close unused apps to reduce processor load.

Laptops and Desktops

Place devices on hard, flat surfaces to allow airflow.

Clean vents and fans regularly.

Use cooling pads or external fans for extra support during gaming or video editing.

Servers and Data Centers

Install temperature sensors to monitor hot spots.

Arrange equipment to optimize airflow.

Schedule regular maintenance for cooling systems.

Battery-Powered Devices

Store batteries in cool, dry places.

Avoid overcharging or deep discharging.

Use devices with advanced battery management systems for better safety and lifespan.

Callout: Implementing the right thermal management solutions for each device type reduces the risk of overheating, improves reliability, and lowers repair costs.

By understanding the differences between passive and active solutions and applying device-specific strategies, users and engineers can ensure that electronics remain safe, efficient, and long-lasting. Effective thermal management strategies protect investments and support the growing demand for high-performance technology.

Spotting Thermal Issues

Warning Signs

Thermal issues often show clear warning signs before causing serious damage. Devices may feel unusually hot to the touch during normal use. Users might notice a sudden drop in performance, such as slower response times or frequent freezing. Unexpected shutdowns or restarts can signal that the device is overheating. In some cases, the battery may drain faster than usual or refuse to charge properly.

A simple checklist helps users identify early signs of thermal problems:

Device feels hot even when idle

Fan noise increases or runs constantly

Screen flickers or displays artifacts

Battery swells or changes shape

System displays temperature warnings

Tip: Regular monitoring of device temperature helps prevent long-term damage. Many devices include built-in sensors that track heat levels and alert users to problems.

When to Get Help

Some thermal issues require professional attention. If a device continues to overheat after basic troubleshooting, users should seek expert help. Signs that call for immediate action include a burning smell, visible smoke, or a battery that appears swollen. These symptoms indicate a risk of fire or permanent damage.

Continuous monitoring systems in data centers and industrial settings detect abnormal temperature changes early. These systems protect equipment and maintain stable performance. For personal devices, users should contact support if they see repeated shutdowns, error messages about overheating, or physical changes in the device.

| Situation | Action to Take |

|---|---|

| Device feels hot briefly | Allow to cool, monitor |

| Frequent overheating | Seek professional help |

| Swollen battery | Stop use, replace |

| Smoke or burning smell | Unplug, get help fast |

Note: Quick response to thermal issues protects both the device and the user. Early intervention keeps performance high and extends device life.

Effective thermal management remains essential for device performance and longevity. Neglecting heat control can lead to costly repairs, safety hazards, and reduced reliability. Experts note that custom cooling channels and uniform temperature distribution help prevent defects and extend operational life. Integrated strategies in electric vehicles also reduce battery aging and improve efficiency.

Custom-designed cooling paths minimize hotspots and material degradation.

Uniform temperature lowers production defects and supports longer-lasting components.

Consider adopting at least one new cooling strategy. Regularly check devices for signs of overheating to ensure safe and reliable operation.

FAQ

What is the most common sign of overheating in electronics?

Most devices feel hot to the touch when overheating. Users may also notice slower performance, loud fan noise, or unexpected shutdowns. These signs suggest the device needs better cooling.

Can using a case cause my phone to overheat?

Yes. Thick or poorly ventilated cases trap heat. Removing the case during heavy use or charging helps the phone stay cooler and perform better.

How often should users clean vents and fans?

Engineers recommend cleaning vents and fans every three to six months. Dust buildup blocks airflow and raises device temperature. Regular cleaning keeps cooling systems efficient.

Do all electronics need active cooling?

Not all devices require active cooling. Low-power gadgets like tablets and e-readers use passive methods. High-performance systems, such as gaming PCs and servers, benefit from fans or liquid cooling.

Improving the Energy Conversion Efficiency of Triboelectric NanogeneratorsSaumitra Jagdale19 November 20242346

Improving the Energy Conversion Efficiency of Triboelectric NanogeneratorsSaumitra Jagdale19 November 20242346There is a huge growth in demand for self-sustaining electronic devices, as the traditional power-generating devices fail in remote and harsh environments due to the periodic requirement of battery changes. Also, these devices are frequency specific; some work only in high frequency and some in low frequency. Triboelectric nanogenerators (TENGs) provide a promising solution by efficiently converting mechanical energy into electricity as they are versatile, compact, and cheap, making them a popular choice.

Read More Methodologies for Increasing Efficiency of Fuel Stack Technology for Energy GenerationSaumitra Jagdale19 November 20242504

Methodologies for Increasing Efficiency of Fuel Stack Technology for Energy GenerationSaumitra Jagdale19 November 20242504Presently, power companies are moving towards renewable energy systems. Conventional energy sources are more expensive because they require a vast network to be maintained and huge human resources. Also, they harm the environment by releasing several harmful gases. As the industry’s focus shifts toward renewable energy sources, energy systems powered by Proton Exchange Membrane Fuel Stacks (PEMFS) are gaining traction.

Read More Reconfigurable Antennas: Improving Efficiency in Modern CommunicationRakesh Kumar, Ph.D.24 December 20242253

Reconfigurable Antennas: Improving Efficiency in Modern CommunicationRakesh Kumar, Ph.D.24 December 20242253This article highlights the limitations of conventional antennas and discusses the advantages of reconfigurable antenna designs. It also explores various reconfiguration techniques, applications, and their potential to enhance efficiency.

Read More The Ultimate Guide to AI Noise Reduction Translation EarbudsUTMEL01 April 20253318

The Ultimate Guide to AI Noise Reduction Translation EarbudsUTMEL01 April 20253318In today’s connected world, talking to others is very important. You’ve likely seen how global business, travel, and learning need easy chats in different languages. This need keeps growing because of new tech like 5G and edge computing. These make fast and smooth connections possible.

Read More Comparing Popular Jumper Wires for Electronics ProjectsUTMEL10 July 2025644

Comparing Popular Jumper Wires for Electronics ProjectsUTMEL10 July 2025644Compare top jumper wires for electronics projects in 2025. Explore options by material, length, gauge, and durability to find the best fit for your needs.

Read More

Subscribe to Utmel !