FPGA vs SoC: A Comprehensive Comparison Guide

Table of Contents

Introduction: Understanding FPGA and SoC Technologies

In today's rapidly evolving digital landscape, hardware engineers and system designers face an increasingly complex decision when selecting the right technology for their projects. Two technologies often at the center of these decisions are Field-Programmable Gate Arrays (FPGAs) and System-on-Chip (SoC) solutions.

Both FPGAs and SoCs offer unique advantages and limitations, with significant implications for system performance, power consumption, time-to-market, and overall project costs. Understanding the fundamental differences between these technologies is crucial for making informed decisions that align with specific project requirements.

This comprehensive guide explores the technical distinctions, performance characteristics, application scenarios, and economic considerations of FPGAs versus SoCs, providing you with the knowledge needed to choose the optimal solution for your next development project.

The Hardware Dilemma

Time-to-market considerations - Balancing development speed with optimization

Performance requirements - Finding the right balance of processing power and efficiency

Power constraints - Meeting energy efficiency demands

Budget limitations - Navigating initial costs versus long-term expenses

Product lifecycle - Planning for maintenance and upgrades

Consider this: Are your project's primary constraints related to development speed, performance, power efficiency, or manufacturing cost? Your answer might significantly influence your hardware technology choice.

Key Definitions

Field-Programmable Gate Array (FPGA)

An FPGA is an integrated circuit designed to be configured after manufacturing. Unlike fixed hardware, FPGAs contain an array of programmable logic blocks and reconfigurable interconnects that allow the same FPGA to be reprogrammed for different tasks, providing exceptional flexibility and customization.

System-on-Chip (SoC)

A SoC integrates all components of a computer or electronic system into a single chip. These components typically include a CPU, memory, input/output ports, and often specialized elements like graphics processors or signal processing units—all on a single integrated circuit, optimized for specific functions.

FPGA including processor vs. SoC including embedded FPGA - showing architectural differences

Architecture and Design: Core Differences

The architectural differences between FPGAs and SoCs are fundamental to understanding their respective strengths and applications. These differences impact everything from development workflows to performance characteristics and power consumption.

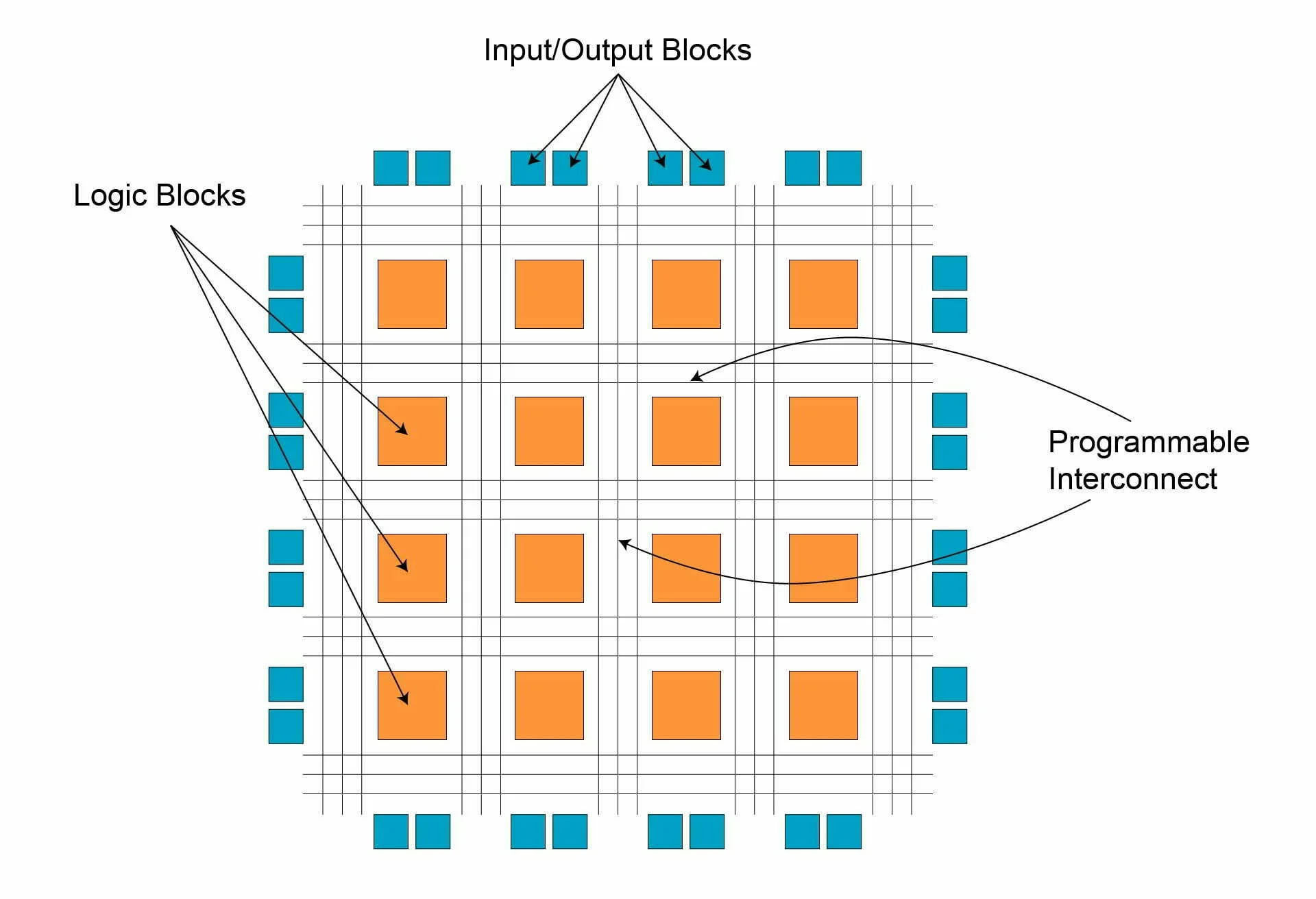

FPGA Architecture

FPGAs consist of a matrix of configurable logic blocks (CLBs) connected via programmable interconnects. This flexible architecture enables hardware-level customization after manufacturing.

Key Components:

Logic Elements/Blocks - Configurable units that implement logical functions

Interconnects - Programmable routing resources between logic blocks

I/O Blocks - Interface with external components

Memory Resources - Embedded block RAM for local storage

DSP Slices - Dedicated blocks for mathematical operations

Clock Management - PLL/DLL resources for timing control

FPGAs excel at parallel processing tasks, implementing custom interfaces, and applications requiring hardware-level optimization. Their reconfigurable nature allows for post-deployment updates and field modifications.

FPGA internal architecture showing logic blocks and interconnect structure

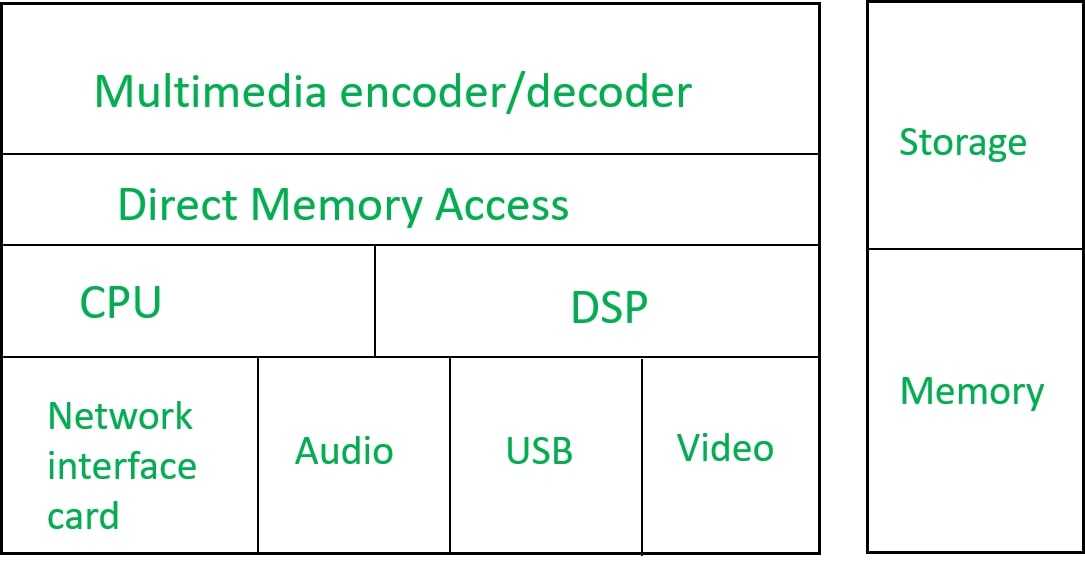

SoC architecture showing integrated processor, memory, and peripheral components

SoC Architecture

System-on-Chip designs integrate multiple subsystems into a single integrated circuit, creating a complete computing platform optimized for specific applications.

Key Components:

Processing Units - CPU cores (often ARM-based)

Memory Subsystems - On-chip RAM and cache hierarchies

Peripheral Controllers - USB, Ethernet, I2C, SPI interfaces

Specialized Accelerators - Graphics, AI, DSP units

Communication Fabric - On-chip bus or network

Power Management - Integrated voltage regulators and controllers

SoCs are designed for specific applications, with hardware and software components optimized to work together. They typically offer better power efficiency and lower per-unit costs at volume than discrete solutions.

Design and Development Process Comparison

| Aspect | FPGA Development | SoC Development |

|---|---|---|

| Design Entry | HDL (VHDL, Verilog), High-Level Synthesis | RTL for hardware, C/C++ for software |

| Development Tools | Vendor-specific IDEs (Vivado, Quartus, etc.) | Various EDA tools, software development environments |

| Verification Approach | Simulation, FPGA-in-loop testing | Extensive simulation, emulation, prototyping |

| Time to Prototype | Hours to days | Weeks to months |

| Design Changes | Quick iteration, field-updatable | Costly and time-consuming |

| Team Expertise | Digital design, HDL programming | Digital design, embedded software, verification |

| Production Readiness | Immediate with existing FPGAs | Requires fabrication and testing |

SoC FPGAs: Hybrid Solutions

The industry has also developed hybrid solutions known as SoC FPGAs, which combine fixed processor systems with reconfigurable FPGA fabric on the same chip. Examples include:

Xilinx Zynq UltraScale+ MPSoC

Intel Agilex SoC FPGAs

Microchip PolarFire SoC FPGA

These hybrid platforms offer the software programmability of processors with the hardware configurability of FPGAs, providing greater design flexibility while reducing system complexity.

Consider this: How might the ability to reconfigure hardware after deployment affect your product's longevity and competitiveness in rapidly evolving markets?

Performance Comparison: Speed, Power, and Flexibility

When evaluating FPGAs against SoCs, engineers must consider multiple performance dimensions. Each technology offers distinct advantages depending on the specific metrics prioritized for a given application.

Processing Speed and Performance

FPGA Performance Characteristics

Parallelism: Excellent for parallel processing tasks

Deterministic timing: Predictable performance for real-time applications

Custom data paths: Optimized for specific algorithms

Clock frequency: Typically lower than dedicated processors (100-500MHz)

Throughput: High for streaming applications due to parallelism

SoC Performance Characteristics

Sequential processing: Excellent for complex control flow

Clock frequency: Higher (often 1-3GHz)

Instruction optimization: Benefiting from modern CPU architectures

Caching: Advanced memory hierarchies improve performance

Specialized accelerators: Purpose-built for specific functions (GPU, DSP, etc.)

For computation-intensive tasks that can be parallelized, FPGAs can outperform general-purpose processors. However, for complex sequential algorithms or when leveraging specialized hardware accelerators, SoCs often provide superior performance.

Power Efficiency

Power consumption is increasingly critical for many applications, especially in battery-operated or thermally constrained environments.

| Power Aspect | FPGA | SoC |

|---|---|---|

| Static Power | Higher due to programmable interconnects | Lower with fixed, optimized circuits |

| Dynamic Power | Can be optimized with custom data paths | Optimized for common workloads |

| Power Management | Limited compared to SoCs | Advanced (multiple domains, dynamic scaling) |

| Performance per Watt | Excellent for specific, optimized functions | Better for general computing tasks |

"In our datacenter AI acceleration project, replacing FPGA-based accelerators with custom SoCs reduced power consumption by 87% while increasing performance by 3.5x. The energy efficiency improvement was transformative for our operating costs."

— Maria Rodriguez, Chief Technology Officer at DataAI Solutions

Flexibility and Adaptation

FPGA Flexibility Advantages

Post-deployment reconfiguration: Hardware can be updated in the field

Adaptation to changing standards: Critical for evolving protocols

Multiple functionalities: Same hardware can serve different purposes

Partial reconfiguration: Parts of the design can be modified while others continue operating

Risk mitigation: Hardware bugs can be fixed without physical replacement

SoC Flexibility Considerations

Software updates: Functionality can be modified through software, but hardware is fixed

Programmable peripherals: Some configurability in I/O and peripheral settings

Multiple operating modes: Can switch between different operating profiles

Hardware limitations: Cannot fundamentally alter processing architecture after fabrication

Resource allocation: Fixed hardware resources must be shared among all functions

Physical Implementation

Physical characteristics impact integration possibilities and manufacturing considerations:

| Physical Aspect | FPGA | SoC |

|---|---|---|

| Silicon Area | Larger due to programmable infrastructure | Smaller, more efficient use of silicon |

| Form Factor | Various packages, typically larger | Highly integrated, smaller packages |

| Integration Level | Often requires additional components | Higher integration, fewer external components |

| Thermal Management | More challenging due to higher power density | More efficient with better power management |

Consider this: Given the performance advantages of SoCs, what specific application requirements might still make FPGAs the better choice despite their performance limitations?

Applications and Use Cases: When to Choose Each

The decision between FPGA and SoC technologies should be driven by specific application requirements, production volumes, and business constraints. Each technology excels in particular scenarios.

FPGA-Favorable Scenarios

Prototyping and R&D: Rapid development and iteration

Low to Medium Volume Production: Below economic crossover point

Evolving Standards: When specifications may change after deployment

Field Upgradability: When post-deployment updates are essential

Time-to-Market Critical: When rapid product introduction is prioritized

Limited Development Budget: When NRE costs must be minimized

Product Customization: When different customers need different configurations

Signal Processing: High-bandwidth data processing applications

Interface Bridging: Connecting incompatible protocols or standards

SoC-Favorable Scenarios

High Volume Production: Above economic crossover point

Mature, Stable Standards: When specifications are unlikely to change

Performance Critical: When maximum speed or minimum latency is required

Power Constrained: Battery-operated or energy-efficient applications

Size Constrained: When minimum form factor is essential

High Security Requirements: When protection against reverse engineering is critical

Consumer Electronics: Mass-market devices with power constraints

Mobile Applications: Smartphones, tablets, wearables

Advanced UI/Graphics: Applications requiring sophisticated displays and user interfaces

Industry-Specific Applications

| Industry | FPGA Applications | SoC Applications |

|---|---|---|

| Telecommunications | 5G prototyping, software-defined radio, protocol adaptation | High-volume base stations, standard network switches, optical transceivers |

| Automotive | ADAS development platforms, reconfigurable dashboards | Production ECUs, airbag controllers, battery management systems |

| Consumer Electronics | Early product prototypes, premium low-volume devices | Smartphones, tablets, smart TVs, game consoles |

| Data Centers | Reconfigurable accelerators, network function virtualization | High-volume AI accelerators, network processors |

| Industrial | Flexible control systems, field-upgradable equipment | High-volume sensors, motor controllers, PLCs |

| Medical | Research equipment, customizable diagnostic devices | High-volume implantable devices, standard monitoring equipment |

| Aerospace & Defense | Radar processing, electronic warfare, mission-specific equipment | Standard avionics, navigation systems, communication equipment |

Real-World Application Examples

Telecommunications Equipment

A major telecommunications equipment manufacturer used FPGAs for their early 5G base station deployment to allow for standard evolution. As 5G standards stabilized, they transitioned high-volume components to SoCs, while maintaining FPGA-based modules for customizable features. This hybrid approach balanced time-to-market, flexibility, and cost optimization.

Automotive ADAS System

An automotive supplier developed an advanced driver assistance system using FPGAs for initial production, allowing them to refine algorithms based on real-world feedback. For the second generation product, they migrated to a custom SoC that reduced power consumption by 75% and unit cost by 60%, but maintained some FPGA components for features still under development.

IoT Sensor Hub

A startup created an IoT sensor hub platform using FPGAs despite projecting volumes that exceeded the traditional SoC crossover point. This decision was driven by the need to support multiple customer-specific protocols and processing configurations. The field programmability enabled them to sell the same hardware with different feature sets at various price points.

Consider this: Could a hybrid approach using both FPGA and SoC components give your product a competitive advantage in your specific market? What functions would you assign to each technology?

FPGA and SoC Integration: The Best of Both Worlds

The distinction between FPGAs and SoCs is increasingly blurred with the emergence of hybrid solutions that combine the strengths of both approaches. This integration takes several forms, each with unique characteristics and applications.

.jpg)

Detailed architecture of an SoC FPGA showing integration of programmable logic with processor system

SoC FPGAs: Integrated Solutions

SoC FPGAs combine a hard processor system (typically ARM-based) with FPGA fabric on a single chip. This integration offers several advantages:

Reduced system complexity - Fewer components, simpler PCB design

Lower latency between processor and programmable logic - High-bandwidth, low-latency interfaces

Shared memory architecture - Simplified data sharing between processor and FPGA

Unified development environment - Integrated tools for hardware and software development

Optimized power management - Coordinated power states across the entire system

Examples of commercial SoC FPGA platforms include Xilinx Zynq UltraScale+ MPSoC, Intel Agilex SoC FPGAs, and Microchip PolarFire SoC.

Embedded FPGAs (eFPGAs) in SoCs

The alternative integration approach involves embedding FPGA fabric within a custom SoC design. This approach is gaining traction as it allows for:

Post-manufacturing hardware customization - Areas of flexibility within a mostly fixed design

Accelerator configurability - Specialized hardware accelerators that can be tuned for specific workloads

Hardware security features - Updatable security functions to address evolving threats

Interface adaptation - Ability to support multiple interface standards with the same silicon

Reduced power compared to discrete FPGAs - Optimized integration reduces power overhead

Companies like Flex Logix and Achronix provide eFPGA IP cores that can be integrated into custom SoC designs.

Development Considerations for Integrated Solutions

| Aspect | Development Considerations |

|---|---|

| Hardware/Software Partitioning | Determining which functions should run in software vs. programmable logic is critical for optimizing performance, power, and flexibility. |

| Communication Interfaces | Understanding the available interfaces between processor and FPGA fabric (AXI, APB, etc.) and their performance characteristics. |

| Resource Allocation | Balancing the allocation of logic resources, DSP blocks, embedded memory, and I/O between different functions. |

| Power Management | Implementing effective power management strategies across both domains, including clock gating, power domains, and low-power modes. |

| Tool Integration | Managing the workflow between hardware design tools (for FPGA) and software development tools (for processor). |

| Debug Methodology | Developing integrated debug approaches that can trace issues across the hardware/software boundary. |

SoC FPGA Use Cases

Industrial Control

SoC FPGAs excel in industrial automation where real-time control algorithms run on the processor while high-speed I/O and protocol implementations use the FPGA fabric. This allows for supporting various industrial protocols (EtherCAT, PROFINET, etc.) with the same hardware platform.

Edge AI

In edge computing applications, the processor handles system management, networking, and pre/post-processing, while the FPGA fabric implements neural network inference accelerators. This combination offers better performance per watt than CPU-only solutions.

Software Defined Radio

SDR platforms use FPGA fabric for signal processing, modulation/demodulation, and filtering, while the processor handles protocol stacks, user interface, and network connectivity. This architecture allows for supporting multiple radio standards with the same hardware.

"Our shift to the Zynq UltraScale+ platform for our vision-guided robotics system resulted in a 40% reduction in PCB size, 35% lower power consumption, and most importantly, cut our development time in half compared to our previous discrete CPU + FPGA approach."

— Dr. James Chen, Senior Hardware Architect at RoboVision Systems

Consider this: For your application, would a SoC FPGA offer the right balance of performance, power, and flexibility compared to either a standalone FPGA or a conventional SoC?

Cost Analysis: Investment vs. Returns

Cost considerations often play a decisive role in choosing between FPGA and SoC implementations. A comprehensive economic analysis must account for both non-recurring engineering (NRE) costs and recurring production costs.

Non-Recurring Engineering (NRE) Costs

NRE costs represent the one-time expenses required to design and prepare for production:

| Cost Category | FPGA | SoC |

|---|---|---|

| Design & Development | $10K - $300K | $500K - $5M+ |

| EDA Tools & Software | $5K - $100K per year | $500K - $2M+ per year |

| IP Licensing | $0 - $100K | $50K - $2M+ |

| Verification | $10K - $200K | $500K - $3M+ |

| Masks & Fabrication Setup | $0 (uses existing FPGA) | $500K - $5M+ |

| Total NRE | $25K - $600K | $2M - $15M+ |

The dramatic difference in NRE costs creates a significant barrier to entry for SoC development, especially for startups and smaller companies. Modern advanced-node SoCs (5nm, 3nm) can have NRE costs exceeding $20M.

Per-Unit Production Costs

While SoCs have much higher NRE costs, they typically have much lower per-unit costs in volume production:

FPGA Unit Cost: Typically ranges from $5 to $5,000+ depending on device size, family, and features. High-end FPGAs for data centers or telecommunications can cost even more.

SoC Unit Cost: Can range from under $1 to $100+ depending on die size, process technology, packaging, and testing requirements. Cost typically decreases with higher volumes due to economies of scale.

Important Consideration

SoC development requires significantly higher upfront investment but can result in lower per-unit costs. However, any design changes after fabrication require new masks and additional NRE expenses, while FPGA designs can be updated with minimal cost.

Volume Break-Even Analysis

The crossover point—the production volume at which SoCs become more cost-effective than FPGAs—depends on several factors:

Typical Crossover Point: Historically between 5,000 and 50,000 units, but varies greatly

Factors Affecting Crossover:

SoC complexity and size

Process node selected

FPGA pricing and volume discounts

Development team expertise

Design lifetime and update frequency

Hidden Costs and Considerations

Beyond the direct development and production costs, several other economic factors should influence the decision:

Time-to-Market Costs

FPGA development cycles are typically 3-6 months, while SoC development can take 12-24 months. The opportunity cost of delayed market entry can exceed the manufacturing cost savings of SoCs. For products in rapidly evolving markets, this consideration alone may favor FPGAs regardless of volume.

Maintenance and Update Costs

FPGAs can be updated after deployment, potentially reducing maintenance costs and extending product life. For SoCs, post-production updates typically require new hardware versions, increasing lifecycle management costs and potentially creating inventory obsolescence issues.

Inventory Risk

SoCs require volume production to be cost-effective, creating inventory risk if sales forecasts aren't met. FPGAs, being general-purpose components, can often be repurposed for other products if forecasts change, reducing overall inventory risk.

Personnel Costs

SoC development typically requires larger, more specialized teams, increasing ongoing personnel costs. FPGA development teams are often smaller and more flexible, potentially reducing personnel overhead, especially for companies with diverse product portfolios.

"Many companies make the mistake of only comparing unit costs when deciding between FPGA and SoC. The true TCO needs to account for development time, opportunity cost, future revision expenses, and product lifecycle. We chose FPGAs for our industrial controller despite planning to ship 30,000 units—above the theoretical crossover point—because time-to-market and field upgradability were critical business requirements."

— Thomas Weber, Hardware Engineering Director at AutomationTech

Consider this: How might emerging technologies like FPGA-to-ASIC conversion services or structured ASICs change the economic equation for your specific product?

Common Misconceptions About FPGA and SoC

Several persistent myths and misconceptions influence decision-making when choosing between FPGAs and SoCs. Understanding these can help avoid costly mistakes.

Misconception 1: "SoCs Are Always More Cost-Effective for High-Volume Production"

Reality: While SoCs typically have lower per-unit costs at high volumes, the total cost of ownership includes factors beyond manufacturing costs. When accounting for development time, risk of design changes, and product lifecycle, FPGAs can sometimes be more economical even at volumes exceeding the traditional crossover point. The emergence of lower-cost FPGA families has also shifted this equation for many applications.

Misconception 2: "FPGAs Are Too Slow for High-Performance Applications"

Reality: Modern high-performance FPGAs feature specialized hardware blocks (DSP slices, embedded memory, high-speed transceivers) and can achieve remarkable performance for specific applications, particularly those that benefit from parallelism. While SoCs maintain an absolute performance advantage, the gap has narrowed significantly. Many demanding applications in telecommunications, financial services, and even AI acceleration successfully deploy FPGA-based solutions.

Misconception 3: "SoC Development Is Only for Large Companies"

Reality: While traditional SoC development has high barriers to entry, newer options have emerged that make custom silicon more accessible. These include multi-project wafers (MPW), FPGA-to-ASIC conversion services, structured ASICs, and rapidly improving EDA tools. Additionally, semiconductor foundries and design houses now offer services tailored to smaller companies and lower volumes.

Misconception 4: "FPGAs Always Consume More Power Than SoCs"

Reality: While SoCs generally have better power efficiency for equivalent functionality, modern FPGAs incorporate numerous power-saving features and process technology advances. For some applications, particularly those requiring only a fraction of the FPGA's resources or benefiting from specialized hard blocks, the power difference may be less significant than anticipated. Careful design practices can also substantially reduce FPGA power consumption.

Misconception 5: "Either FPGA or SoC Is the Right Answer"

Reality: Many successful products employ hybrid approaches, using SoCs for stable, performance-critical functions and FPGAs for evolving features or customization. Some products also start with FPGAs and migrate selected functions to SoCs over time as volumes increase and requirements stabilize. The choice isn't always binary.

Misconception 6: "FPGA Design Is Too Difficult for Software Engineers"

Reality: While FPGA development traditionally required hardware design expertise, modern high-level synthesis tools enable software engineers to implement FPGA designs using languages like C/C++ and OpenCL. Development environments have become more accessible, with higher-level abstractions that hide many of the hardware complexities. The learning curve remains steeper than traditional software development, but it's increasingly accessible to software engineers.

Consider this: Which of these misconceptions might be influencing your team's technology decisions? How could challenging these assumptions lead to better architectural choices?

Purchase Suggestions: Top FPGA and SoC Products

If you've determined that an FPGA or SoC FPGA is the right choice for your application, here are some recommended options currently available on the market.

Hot-Selling FPGAs in 2023

Xilinx Zynq UltraScale+ FPGA/SoC

Model: XCZU3EG-1SFVC784E

A powerful SoC FPGA combining quad-core ARM Cortex-A53 processors with FPGA fabric, ideal for embedded vision, industrial automation, and communications applications requiring both software and hardware acceleration.

Quad ARM Cortex-A53 MPCore processor

Dual ARM Cortex-R5 real-time processor

154K+ programmable logic cells

Operating temperature: 0°C~100°C TJ

Lattice CrossLink-NX FPGA

Model: LIFCL-40-9BG400C

Ultra-low power FPGA optimized for embedded vision applications, offering excellent performance/watt ratio in a compact package, perfect for edge AI and IoT applications with strict power constraints.

39,000 logic elements

1.0V operating voltage

Up to 10 Gbps data rate

Low power consumption

Operating temperature: 0°C ~ 85°C

Intel Agilex F-Series SoC FPGA

Model: AGFB014R24B2E4X

Intel's advanced SoC FPGA platform combining ARM Cortex-A53 processors with high-performance FPGA fabric, offering exceptional processing power for data-intensive applications like networking, computing acceleration, and signal processing.

Quad ARM Cortex-A53 MPCore processor

1.4 million logic elements

1.4 GHz processor speed

Advanced power management

Operating temperature: 0°C ~ 100°C (TJ)

FPGA Selection Checklist

When choosing an FPGA for your project, consider these key factors:

Logic Resources: Ensure the device has sufficient logic cells, flip-flops, and LUTs for your design.

Memory Requirements: Evaluate on-chip memory (Block RAM) capacity for buffers and local storage.

I/O Requirements: Count the number and types of I/O pins needed for your application.

Special Resources: Consider requirements for DSP blocks, high-speed transceivers, or hard processor cores.

Power Budget: Analyze power constraints, especially for battery-operated or heat-sensitive applications.

Development Ecosystem: Evaluate available tools, IP cores, and community support.

Supply Chain: Check lead times, lifecycle status, and long-term availability.

Cost: Compare both unit cost and development tool expenses.

Additional Resources for FPGA Selection

For more detailed guidance on selecting FPGAs and comparing them with other technologies, check out these resources:

FPGA vs ASIC: Comprehensive Comparison Guide - Detailed analysis of the differences between FPGAs and ASICs

FPGA vs Microcontroller Technology: Similarities and Differences - Comparison of FPGAs with traditional microcontrollers

Intel FPGA Product Information - Comprehensive resource for Intel FPGA products

Xilinx SoC FPGA Information - Details on Xilinx's SoC FPGA offerings

Lattice Semiconductor Product Selection Guide - Resource for low-power FPGA options

Consider this: Beyond the basic specifications, what unique project requirements should influence your FPGA or SoC selection? Consider factors like long-term support, IP availability, and ecosystem maturity.

Future Trends: The Evolution of FPGA and SoC Technologies

The hardware acceleration market continues to evolve rapidly, with several emerging trends influencing the FPGA vs SoC decision. Understanding these trends can help engineers make forward-looking decisions that accommodate future developments.

Technology Convergence

The traditional boundaries between FPGAs and SoCs are blurring with the emergence of hybrid and intermediate solutions:

Adaptive Computing Platforms: Modern devices like Xilinx Versal combine FPGA fabric with hardened compute engines and programmable network-on-chip, offering SoC-like performance with FPGA flexibility.

Structured ASICs: Solutions like Intel eASIC provide an intermediate option with lower NRE costs than full-custom SoCs but better performance than FPGAs.

FPGA-to-ASIC Conversion: Services that can convert validated FPGA designs to ASICs, allowing a progressive approach to hardware development.

Chiplets and Advanced Packaging: Enabling the integration of FPGA fabric with SoC components in the same package, allowing for more modular and heterogeneous system design.

Specialized Solutions for Emerging Applications

New application domains are driving innovation in both FPGA and SoC technologies:

AI Acceleration: Both FPGAs and SoCs are evolving to better support neural network inference and training, with specialized architectures for different AI workloads.

Edge Computing: Low-power FPGAs optimized for edge deployment are enabling more processing at the network edge while maintaining power efficiency.

Quantum Computing: FPGAs are finding roles in quantum control systems and as classical co-processors in hybrid quantum-classical systems.

6G and Beyond: Advanced communications are driving development of specialized RF-integrated programmable platforms combining SoC capabilities with FPGA flexibility.

Accessibility and Development Improvements

Tools and methodologies are evolving to lower the barriers to hardware development:

High-Level Synthesis

Advanced tools allow developers to program FPGAs and SoCs using C/C++, Python, or domain-specific languages rather than traditional HDLs. This evolution opens hardware development to a broader pool of software engineers and accelerates development cycles.

Open-Source Hardware

RISC-V and other open-source initiatives are creating more accessible paths to custom silicon. Open-source tools like Yosys for synthesis and nextpnr for place and route are maturing, reducing dependency on proprietary vendor tools.

AI-Assisted Design

Machine learning techniques are being applied to EDA tools to improve design quality and reduce development time. AI can optimize placement, routing, and timing closure, potentially addressing some of the most challenging aspects of FPGA design.

Market Growth Projections

Both FPGA and SoC markets continue to show strong growth, driven by different but complementary factors:

FPGA Market Trends

The global FPGA market is projected to reach $13.2 billion by 2026, with a CAGR of 8.5%

Growth drivers include AI/ML applications, 5G infrastructure, and automotive advanced driver assistance systems

Increasing adoption in edge computing and IoT applications

Rising demand for adaptive computing in data centers

SoC Market Trends

The SoC market is expected to grow to $274.9 billion by 2025, at a CAGR of 11.7%

Key growth segments include consumer electronics, automotive, and industrial automation

Increasing integration of AI acceleration in mainstream SoCs

Growing demand for specialized SoCs optimized for specific workloads

Consider this: How might your hardware selection strategy need to evolve as technologies converge and new hybrid options emerge in the coming years?

Conclusion: Making the Right Choice for Your Project

The decision between FPGA and SoC implementation is multifaceted and depends on careful analysis of your specific requirements, constraints, and business objectives. Both technologies offer unique advantages that can be leveraged in different scenarios.

Key Decision Factors Recap

Development Resources: Consider your team's expertise, available development budget, and timeframe constraints.

Production Volume: Evaluate expected lifetime volume against the economic crossover point.

Performance Requirements: Assess if your application needs the absolute highest performance or if FPGA capabilities are sufficient.

Power and Size Constraints: Determine how critical power efficiency and form factor are for your application.

Flexibility Needs: Consider the importance of field upgradability and adaptation to evolving standards.

Risk Tolerance: Evaluate your organization's ability to absorb the higher risk of SoC development.

Consider Hybrid Approaches

Don't overlook the potential for hybrid approaches that combine the strengths of both technologies:

Using SoCs for stable, high-performance functions alongside FPGAs for configurable elements

Starting with FPGAs for market validation before transitioning to SoCs for cost reduction

Utilizing SoC FPGAs that combine processor systems with programmable logic

Exploring intermediate solutions like structured ASICs or FPGA-to-ASIC conversion paths

"The most successful hardware strategies we've implemented don't view FPGA vs SoC as a binary choice, but rather as complementary technologies that can be deployed strategically throughout a product's lifecycle and across different components of a system."

— Dr. Sarah Johnson, VP of Hardware Engineering at Quantum Solutions Inc.

Final Thoughts

As the hardware landscape continues to evolve, successful organizations maintain expertise in both FPGA and SoC development, allowing them to select the optimal approach for each project based on its unique requirements. The key is to thoroughly understand the tradeoffs and make informed decisions aligned with both technical needs and business objectives.

Consider this: What steps can your organization take to maintain flexibility in hardware platform choices while still optimizing for your most critical requirements?

Frequently Asked Questions

Q1: What is the fundamental difference between FPGA and SoC technologies?

The fundamental difference is that FPGAs (Field-Programmable Gate Arrays) can be reconfigured after manufacturing, while SoCs (System-on-Chips) integrate multiple fixed components like processors, memory, and peripherals on a single chip. FPGAs offer flexibility and faster time-to-market but typically have higher per-unit costs and lower performance, while SoCs offer superior performance and lower unit costs but require significant upfront investment and longer development cycles.

Q2: At what production volume does SoC become more cost-effective than FPGA?

The crossover point typically ranges from 5,000 to 50,000 units, but varies significantly based on specific factors including design complexity, SoC process node, FPGA pricing, development team expertise, and potential for future design changes. Some high-complexity designs might have crossover points exceeding 100,000 units, while simpler designs using older process nodes might reach crossover at lower volumes.

Q3: How much better is SoC performance compared to FPGA?

SoCs typically offer 3-10x higher clock frequencies, 5-10x lower power consumption, and require 10-20x less silicon area compared to equivalent FPGA implementations. However, these ratios vary widely depending on the specific application, design optimization efforts, and the generation of technologies being compared. Some specialized functions where FPGAs have dedicated hardened blocks might show smaller performance gaps.

Q4: Can I start with FPGA and later move to SoC?

Yes, this is a common strategy called the "FPGA-to-SoC" path. It allows companies to validate designs and enter the market quickly using FPGAs, then transition to SoCs when volumes justify the investment. Several vendors offer services specifically for this migration path, and design practices can be adopted early to facilitate the eventual transition. However, optimal SoC designs often differ from optimal FPGA designs, so some redesign is typically required for best results.

Q5: What are SoC FPGAs and how do they compare to traditional FPGAs and SoCs?

SoC FPGAs integrate a hard processor system (typically ARM-based) with FPGA fabric on a single chip. They offer the processing power and efficiency of SoCs for software tasks while maintaining the flexibility of FPGAs for hardware acceleration and customization. Compared to traditional FPGAs, they provide better processing performance and lower power for software tasks. Compared to standard SoCs, they offer greater flexibility through the reconfigurable logic. Examples include Xilinx Zynq, Intel Agilex SoC, and Microchip PolarFire SoC.

Discovering New and Advanced Methodology for Determining the Dynamic Characterization of Wide Bandgap DevicesSaumitra Jagdale15 March 20242410

Discovering New and Advanced Methodology for Determining the Dynamic Characterization of Wide Bandgap DevicesSaumitra Jagdale15 March 20242410For a long era, silicon has stood out as the primary material for fabricating electronic devices due to its affordability, moderate efficiency, and performance capabilities. Despite its widespread use, silicon faces several limitations that render it unsuitable for applications involving high power and elevated temperatures. As technological advancements continue and the industry demands enhanced efficiency from devices, these limitations become increasingly vivid. In the quest for electronic devices that are more potent, efficient, and compact, wide bandgap materials are emerging as a dominant player. Their superiority over silicon in crucial aspects such as efficiency, higher junction temperatures, power density, thinner drift regions, and faster switching speeds positions them as the preferred materials for the future of power electronics.

Read More A Comprehensive Guide to FPGA Development BoardsUTMEL11 September 202511490

A Comprehensive Guide to FPGA Development BoardsUTMEL11 September 202511490This comprehensive guide will take you on a journey through the fascinating world of FPGA development boards. We’ll explore what they are, how they differ from microcontrollers, and most importantly, how to choose the perfect board for your needs. Whether you’re a seasoned engineer or a curious hobbyist, prepare to unlock new possibilities in hardware design and accelerate your projects. We’ll cover everything from budget-friendly options to specialized boards for image processing, delve into popular learning paths, and even provide insights into essential software like Vivado. By the end of this article, you’ll have a clear roadmap to navigate the FPGA landscape and make informed decisions for your next groundbreaking endeavor.

Read More Applications of FPGAs in Artificial Intelligence: A Comprehensive GuideUTMEL29 August 20252913

Applications of FPGAs in Artificial Intelligence: A Comprehensive GuideUTMEL29 August 20252913This comprehensive guide explores FPGAs as powerful AI accelerators that offer distinct advantages over traditional GPUs and CPUs. FPGAs provide reconfigurable hardware that can be customized for specific AI workloads, delivering superior energy efficiency, ultra-low latency, and deterministic performance—particularly valuable for edge AI applications. While GPUs excel at parallel processing for training, FPGAs shine in inference tasks through their adaptability and power optimization. The document covers practical implementation challenges, including development complexity and resource constraints, while highlighting solutions like High-Level Synthesis tools and vendor-specific AI development suites from Intel and AMD/Xilinx. Real-world applications span telecommunications, healthcare, autonomous vehicles, and financial services, demonstrating FPGAs' versatility in mission-critical systems requiring real-time processing and minimal power consumption.

Read More 800G Optical Transceivers: The Guide for AI Data CentersUTMEL24 December 20252051

800G Optical Transceivers: The Guide for AI Data CentersUTMEL24 December 20252051The complete guide to 800G Optical Transceiver standards (QSFP-DD vs. OSFP). Overcome supply shortages and scale your AI data center with Utmel Electronic.

Read More Xilinx FPGAs: From Getting Started to Advanced Application DevelopmentUTMEL09 September 20253716

Xilinx FPGAs: From Getting Started to Advanced Application DevelopmentUTMEL09 September 20253716This guide is your comprehensive roadmap to understanding and mastering the world of Xilinx FPGA technology. From selecting your first board to deploying advanced AI applications, we'll cover everything you need to know to unlock the potential of these remarkable devices. The global FPGA market is on a significant growth trajectory, expected to expand from USD 8.37 billion in 2025 to USD 17.53 billion by 2035. This surge is fueled by the relentless demand for high-performance, adaptable computing in everything from 5G networks and data centers to autonomous vehicles and the Internet of Things (IoT). This guide will walk you through the key concepts, tools, and products in the Xilinx ecosystem, ensuring you're well-equipped to be a part of this technological revolution.

Read More

Subscribe to Utmel !

![ATSHA204A-RBHCZ-B]() ATSHA204A-RBHCZ-B

ATSHA204A-RBHCZ-BMicrochip Technology

![ACPL-K342-560E]() ACPL-K342-560E

ACPL-K342-560EBroadcom Limited

![1EDC40I12AHXUMA1]() 1EDC40I12AHXUMA1

1EDC40I12AHXUMA1Infineon Technologies

![HCS362T-I/SN]() HCS362T-I/SN

HCS362T-I/SNMicrochip Technology

![AT88SC0104CA-TH-T]() AT88SC0104CA-TH-T

AT88SC0104CA-TH-TMicrochip Technology

![ADATE304BBCZ]() ADATE304BBCZ

ADATE304BBCZAnalog Devices Inc.

![DLP3310FQM]() DLP3310FQM

DLP3310FQMTexas Instruments

![FOD3182V]() FOD3182V

FOD3182VON Semiconductor

![FM31256-G]() FM31256-G

FM31256-GCypress Semiconductor Corp

![HCPL-3180-000E]() HCPL-3180-000E

HCPL-3180-000EBroadcom Limited