Carbon Film vs Metal Film Resistors: Complete Comparison Guide

Table of Contents

Introduction to Film Resistors

When designing electronic circuits, choosing the right components is crucial for ensuring optimal performance and reliability. Resistors are fundamental components in almost every electronic device, and selecting between carbon film resistors and metal film resistors can significantly impact your circuit's performance, reliability, and cost-effectiveness.

As an electronics engineer or hobbyist, you've likely faced the dilemma: "Should I use carbon film or metal film resistors for this project?" This comprehensive guide aims to solve this common pain point by providing a detailed comparison, helping you make informed decisions based on your specific requirements.

Today's electronics demand precise component selection, and resistors are no exception. Whether you're building audio equipment, power supplies, or precision measurement devices, understanding the differences between carbon film and metal film resistors will enable you to optimize your designs and avoid potential issues down the line.

Have you ever wondered: Why do some audiophiles swear by carbon film resistors while precision instruments typically use metal film resistors? By the end of this article, you'll understand exactly why.

What Are Resistors?

Before diving into the specific types, let's briefly review what resistors do in electronic circuits:

Resistors are passive two-terminal electrical components that implement electrical resistance as a circuit element. Their primary function is to restrict the flow of electric current, and they're used for:

Current limiting

Voltage division

Biasing active components

Setting time constants with capacitors

Matching and loading circuits

Heat generation in some applications

Film resistors represent one of the most common types of resistors used in modern electronics. They consist of a resistive material deposited as a thin film onto an insulating substrate, with metal leads or end caps for circuit connections.

Carbon Film Resistors: Structure and Characteristics

What is a Carbon Film Resistor?

Carbon film resistors, also called thermal decomposition carbon film resistors, are created by depositing a thin layer of carbon onto a ceramic substrate. This is done by thermally decomposing a hydrocarbon at high temperatures in a vacuum, resulting in carbon being tightly attached to the surface of a porcelain rod.

The surface is typically coated with epoxy resin for protection, giving these resistors their characteristic green appearance (though colors may vary). The thickness of the carbon film determines the resistance value, which can be further adjusted by cutting spiral grooves into the film.

Carbon film resistor structure

Basic Structure of Carbon Film Resistors

The typical structure of a carbon film resistor includes:

Ceramic substrate (typically a rod or tube)

Carbon film layer deposited on the substrate

Spiral groove cut into the film to increase resistance path

End caps or terminations for electrical connections

Lead wires for through-hole mounting

Protective coating, usually epoxy resin

Detailed structure of a carbon film resistor showing substrate, film, and terminations

Key Characteristics of Carbon Film Resistors

| Parameter | Specification |

|---|---|

| Resistance Range | 1Ω to 10MΩ |

| Tolerance | ±2% to ±5% (typically) |

| Temperature Coefficient | -200 to -1000 ppm/K (negative) |

| Rated Power | 0.125W, 0.25W, 0.5W, 1W, 2W, 5W, 10W |

| Operating Temperature | -55°C to +155°C |

| Noise Level | Moderate (below 10µV/V) |

| Voltage Coefficient | -10 ppm/V |

"Carbon film resistors have low cost, poor electrical performance, and stability, and they are generally not suitable for general-purpose resistors. But because it is easy to make a high resistance film, it is mainly used as a resistor of high resistance and voltage, which is the same as high-voltage resistors." - UTMEL Blog

Metal Film Resistors: Structure and Characteristics

What is a Metal Film Resistor?

Metal film resistors are precision components manufactured by depositing a thin layer of metal alloy (typically nickel-chromium) onto a ceramic substrate. The deposition is typically done through vacuum evaporation or sputtering techniques, creating a highly uniform and stable resistive element.

These resistors are recognized for their high precision, stability, and reliability, making them suitable for applications where accuracy is crucial. The resistance value can be precisely adjusted by cutting a helical groove through the metal film, increasing the effective path length of current flow.

Metal film resistor structure

Basic Structure of Metal Film Resistors

The construction of a metal film resistor typically includes:

Ceramic substrate (usually high-purity alumina)

Metal alloy film (often nickel-chromium) deposited on the substrate

Precision helical cut to adjust resistance value

End caps or terminations for electrical connections

Lead wires (typically tinned copper)

Protective coating (often blue in color)

Detailed structure showing the construction of a metal film resistor

Key Characteristics of Metal Film Resistors

| Parameter | Specification |

|---|---|

| Resistance Range | 1Ω to 1000MΩ |

| Tolerance | ±0.1%, ±0.25%, ±0.5%, ±1% (typically) |

| Temperature Coefficient | ±20 to ±200 ppm/K (small positive) |

| Rated Power | 0.125W, 0.25W, 0.5W, 1W, 2W, 10W, 25W |

| Operating Temperature | -55°C to +155°C (can reach 350°C in some designs) |

| Noise Level | Very low (significantly less than carbon film) |

| Voltage Coefficient | Just under 1 ppm/V |

"Metal film resistors have higher accuracy, better stability, noise and temperature coefficient calibration than carbon film resistors, and are widely used in instrumentation and communication equipment." - UTMEL Blog

Key Differences Between Carbon Film and Metal Film Resistors

| Parameter | Carbon Film Resistors | Metal Film Resistors |

|---|---|---|

| Composition | Carbon deposited on ceramic | Metal alloy (typically NiCr) deposited on ceramic |

| Appearance | Often khaki or green | Typically blue |

| Precision/Tolerance | ±2% to ±5% (typically) | ±0.1% to ±1% (higher precision) |

| Temperature Coefficient | -200 to -1000 ppm/K (negative) | ±20 to ±200 ppm/K (lower, more stable) |

| Noise Generation | Moderate | Low (better for audio/precision applications) |

| Stability | Moderate | High |

| High-Frequency Performance | Moderate (usable to ~1MHz) | Excellent (usable to ~100MHz) |

| Cost | Lower | Slightly higher |

| Typical Color Code | 4 bands | 5 bands (for higher precision) |

| Pulse Load Stability | Better | Poorer |

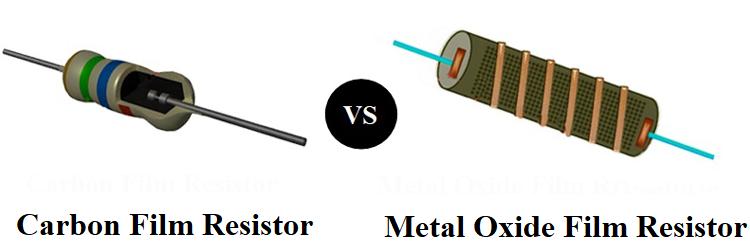

Visual comparison of carbon film and metal film resistors

Strengths and Weaknesses Analysis

Carbon Film Resistors

Strengths

Cost-Effective: Lower manufacturing cost makes them budget-friendly for large-scale productions

Pulse Handling: Better ability to handle power surges and pulse loads

High Voltage Applications: Well-suited for high voltage circuit designs

Wide Resistance Range: Can be manufactured with a wide range of resistance values

Warm Sound Character: Preferred by some audiophiles for their "warmer" sound signature in audio equipment

Weaknesses

Lower Precision: Typically only available in ±2% to ±5% tolerance

Temperature Sensitivity: Higher temperature coefficient means more resistance variation with temperature changes

Noise Generation: Higher inherent noise can be problematic in sensitive applications

Aging Effect: More prone to resistance drift over time

Metal Film Resistors

Strengths

High Precision: Available in tolerances as tight as ±0.1%

Excellent Stability: Maintains resistance value over time and environmental conditions

Low Noise: Significantly less noise generation, ideal for audio and sensitive measurement circuits

Superior Temperature Coefficient: Much less variation with temperature changes

Excellent High-Frequency Response: Better performance in RF and high-speed circuits

Weaknesses

Higher Cost: More expensive manufacturing process

Poorer Pulse Handling: Less suitable for applications with significant power surges

Less "Character" in Audio: Some audiophiles claim they sound "colder" or "more clinical" in audio circuits

Think about it: Given that metal film resistors generally have better electrical characteristics, why do some high-end audio equipment manufacturers still use carbon film resistors in certain signal path applications?

Application Scenarios

Choosing the right type of resistor depends on the specific requirements of your application. Here's a guide to help you select the appropriate resistor type based on common application scenarios:

When to Use Carbon Film Resistors

High Voltage Applications: Carbon film resistors can handle high voltages up to 15 kV in some designs

Pulse-Rich Environments: Better suited for circuits subjected to power surges or pulses

Cost-Sensitive Projects: When budget constraints are significant and high precision isn't required

Vintage Audio Equipment: Where the characteristic "sound" of carbon resistors is desired

High-Temperature Applications: Some variants can operate at temperatures up to 350°C

Power Supplies and Adapters: Common in less precision-sensitive power supply circuits

"Carbon film resistors are widely used in electron, electric appliances, and information products. They have the cheapest price and high reliability in quality stability." - UTMEL Blog

When to Use Metal Film Resistors

Precision Instrumentation: Where high accuracy and stability are critical

Audio Signal Paths: When low noise is essential for high-fidelity sound reproduction

Medical Devices: Where reliability and consistency are paramount

Test and Measurement Equipment: For accurate and stable reference circuits

RF Circuits: Better high-frequency performance is needed

Temperature-Sensitive Applications: Where resistance value must remain stable across temperature variations

Low-Noise Amplifiers: Where minimal circuit noise is crucial

Engineer's Experience: John's Precision Instrument Challenge

"I was developing a sensitive environmental monitoring device that needed to operate reliably in temperatures from -10°C to +50°C. Initially, I used carbon film resistors to save costs, but found that the readings would drift significantly with temperature changes, causing calibration issues. After switching to metal film resistors with their tighter temperature coefficient, the readings remained consistent across the entire temperature range, solving our precision problems. The slightly higher component cost was negligible compared to the improved performance and reduced calibration needs."

Audiophile's Perspective: Maria's Tube Amplifier Project

"When building my custom tube amplifier, I initially used metal film resistors throughout for their precision and low noise. The amplifier sounded technically perfect but lacked a certain 'warmth' I was looking for. After experimenting, I replaced several key resistors in the signal path with carbon film types. While this technically introduced more noise, the subtle harmonic distortion actually enhanced the sound for my taste, giving the music a more 'analog' quality. This taught me that sometimes the technically 'best' component isn't always the right choice for every application."

Film Resistors in Audio Applications

Audio circuits represent one of the most interesting application areas for comparing carbon film and metal film resistors, as this is where subjective factors sometimes contradict technical specifications.

Carbon Film in Audio

Many tube audiophiles prefer carbon film resistors for their unique characteristics:

Creates a warmer, softer sound with thicker midrange

Introduces a subtle, sometimes desirable form of distortion

Often used in vintage equipment reproduction

Some audiophiles claim they produce a more "musical" sound

"Many tube audiophiles still love to use carbon (non-inductive) resistors. They say carbon resistors are somewhat noisy but good for warm, soft and thick-mid sounds." - diyAudio Forum

Metal Film in Audio

Modern high-fidelity designs typically favor metal film resistors:

Significantly lower noise floor

More accurate signal reproduction

Cleaner, more detailed high frequencies

Better channel matching for stereo applications

More consistent performance over time

"Metal films are quieter and cleaner; they pick up less noise and therefore distort less." - Gearspace Forum

Question to consider: In your audio projects, have you ever noticed audible differences when changing resistor types? What specific characteristics did you observe?

How to Choose the Right Resistor: Purchase Guide

When selecting between carbon film and metal film resistors for your projects, consider the following factors:

Decision Factors

| If You Need | Choose | Reasoning |

|---|---|---|

| Precision ±1% or better | Metal Film | Metal film offers tighter tolerances and better stability |

| Low noise in sensitive circuits | Metal Film | Significantly lower noise generation |

| Stable operation across temperatures | Metal Film | Much lower temperature coefficient |

| Lowest cost for general use | Carbon Film | More economical manufacturing process |

| High voltage applications | Carbon Film | Better high-voltage handling capabilities |

| Pulse handling capability | Carbon Film | Superior performance with sudden power surges |

| RF circuit applications | Metal Film | Better high-frequency characteristics |

| "Warm" sound in audio | Carbon Film | Characteristic distortion considered pleasing by some |

| Detailed, accurate audio | Metal Film | Lower noise floor and distortion |

Practical Purchasing Tips

For general electronics projects, 1% metal film resistors are recommended as the standard choice unless you have specific reasons to use carbon film

When purchasing carbon film resistors, be aware of their higher tolerance values (typically 5%)

For hobbyist projects where exact precision isn't critical, carbon film resistors can offer significant cost savings

When buying metal film resistors, verify they are truly metal film by checking for 5-band color codes (a common indicator of 1% tolerance)

For audio applications, consider purchasing both types to experiment with their different sonic characteristics

Always buy from reputable suppliers, as there have been reports of mislabeled resistors being sold online

"In most cases, 1% metal film resistors have become the standard for all but the most cost-sensitive applications, due to their superior performance characteristics and relatively small price premium over carbon film types." - EE Times

Consider this: When would the cost difference between metal film and carbon film resistors become significant enough to impact your component selection for a large production run?

🔹 Carbon Film Resistor – Common Part Numbers

| Part Number | Specification | Manufacturer | Description |

|---|---|---|---|

| CF1/4CT52R100J | 100Ω, 1/4W, ±5% | KOA Speer | CF series standard carbon film |

| CF1/2CT52R1K0J | 1kΩ, 1/2W, ±5% | KOA Speer | General-purpose carbon resistor |

| RSF250JR-52-1K | 1kΩ, 1/4W, ±5% | Yageo | RSF series carbon film |

| CF25J1K0 | 1kΩ, 1/4W, ±5% | ROYAL OHM | Taiwan Royal Ohm CF resistor |

| CR25J100Ω | 100Ω, 1/4W, ±5% | UniOhm | CR series carbon film resistor |

🔹 Metal Film Resistor – Common Part Numbers

| Part Number | Specification | Manufacturer | Description |

|---|---|---|---|

| MFR-25FBF52-1K | 1kΩ, 1/4W, ±1% | Yageo | MFR-25 series, general-purpose |

| MF1/4DCT52R1K00F | 1kΩ, 1/4W, ±1% | KOA Speer | Precision metal film resistor |

| CMF551K0000FHEB | 1kΩ, 1/4W, ±1% | Vishay/Dale | CMF55 series, high-precision type |

| RN55D1001F | 1kΩ, 1/8W, ±1% | Vishay/Dale | RN series, military grade |

| MFR1W-1K-1% | 1kΩ, 1W, ±1% | ROYAL OHM | Higher power metal film resistor |

Common Misconceptions

Misconception #1: Metal Film Resistors Are Always Better

Reality: While metal film resistors have superior electrical characteristics in many areas, carbon film resistors still excel in specific applications such as high voltage environments, pulse handling, and certain audio applications where their particular characteristics are desired.

Misconception #2: Carbon Film Resistors Are Obsolete

Reality: Carbon film resistors remain in production and are widely used for many applications. Their unique characteristics, cost advantages, and specific performance benefits ensure their continued relevance in modern electronics.

Misconception #3: The Color Indicates the Type

Reality: While there's often a correlation (metal film resistors are commonly blue, carbon film often green or beige), color alone is not a reliable indicator. The most accurate way to identify the type is by looking at the markings, specifications, or testing the component.

Misconception #4: Higher Precision Always Matters

Reality: In many circuits, the tight tolerances of metal film resistors (±1% or better) provide no practical advantage over the ±5% of carbon film resistors. Circuit design often accommodates component variations, making the higher precision unnecessary in many applications.

Selection Checklist of Options

Resistor Selection Checklist

Recommendation Summary:

For general electronics: 1% metal film resistors

For cost-sensitive applications: 5% carbon film resistors

For precision circuits: 0.1% or 0.5% metal film resistors

For high voltage applications: Carbon film or metal oxide film resistors

For audio signal path: Test both types for desired sound character

Reflect on this: Does your typical component selection process include all these factors, or do you tend to default to one type of resistor out of habit?

Frequently Asked Questions

How can I visually distinguish between carbon film and metal film resistors?

While not entirely reliable, there are several visual clues to differentiate them:

Color: Metal film resistors are often blue, while carbon film resistors are typically green, beige, or tan.

Color bands: Metal film resistors typically have 5 color bands (for 1% tolerance), while carbon film resistors often have 4 bands (for 5% tolerance).

Film appearance: If you scrape the protective coating carefully, carbon film will appear black underneath, while metal film will appear bright or silvery.

The most reliable method is to check the manufacturer's specifications or test the resistor's characteristics.

Can I replace carbon film resistors with metal film resistors in my circuit?

In most cases, yes. Metal film resistors generally have superior electrical characteristics and can replace carbon film resistors as long as:

The resistance value and power rating are the same

The physical size fits in the available space

The application doesn't specifically require the pulse handling capability of carbon film resistors

The circuit doesn't rely on the specific characteristics of carbon film resistors (such as certain audio applications)

Do metal film resistors always sound better in audio circuits?

Not necessarily. While metal film resistors have objectively better electrical characteristics (lower noise, better stability), audio appreciation involves subjective factors as well.

Some audiophiles prefer the sound of carbon film resistors in certain positions of the signal path, particularly in tube amplifiers, because they can impart a "warmer" character to the sound. This is technically a form of distortion, but it may be perceived as pleasant.

For critical applications like studio equipment where accuracy is paramount, metal film resistors are generally preferred. For some consumer audio equipment, especially those aiming for a "vintage" sound, carbon film resistors might be deliberately chosen.

Why do carbon film resistors have a negative temperature coefficient?

Carbon film resistors have a negative temperature coefficient due to the intrinsic properties of carbon as a semiconductor material. When the temperature increases, more electrons in the carbon become excited and can participate in conduction. This causes the resistance to decrease as temperature rises.

This behavior is different from metals, which typically increase in resistance with temperature (positive temperature coefficient). The crystalline structure of the carbon film and the manufacturing process contribute to this characteristic.

This property must be taken into account when designing circuits that will operate across a wide temperature range, as it can affect the circuit's behavior.

Are metal film resistors worth the extra cost?

In most modern applications, yes. The price difference between carbon film and metal film resistors has decreased significantly over the years, making the performance benefits of metal film resistors well worth the slight premium:

Their higher precision reduces the need for circuit calibration

Their better stability means less drift over time, potentially extending the product's service life

Their lower noise benefits any sensitive or high-gain circuit

Their better temperature stability improves operation across various environments

However, for high-volume, cost-sensitive products where precision isn't critical, carbon film resistors may still be the economical choice.

Conclusion

The choice between carbon film and metal film resistors represents a classic engineering trade-off between performance and cost, with each type offering distinct advantages in specific applications.

Carbon film resistors continue to serve important roles in cost-sensitive applications, high-voltage environments, pulse-handling circuits, and situations where their unique characteristics—including their "sound" in audio applications—are valued. Their lower cost and robust nature ensure they remain relevant in modern electronics.

Metal film resistors have become the de facto standard for many applications due to their superior precision, stability, lower noise, and excellent high-frequency performance. While slightly more expensive than carbon film resistors, their enhanced characteristics often justify the cost difference, especially in precision applications.

Understanding the strengths and limitations of each resistor type enables engineers and hobbyists to make informed decisions based on their specific application requirements rather than simply defaulting to one type for all situations.

As with many component choices in electronics, the "best" resistor is the one that meets the specific requirements of your application while considering practical constraints like cost, availability, and performance needs.

Further Learning Resources

Understanding of Carbon Film Resistors - comprehensive guide to carbon film resistors

Basic Introduction to Metal Film Resistor - detailed information on metal film resistors

Selecting Resistors for High-End Audio Applications - EE Times guide for audio circuits

Resistor Materials Guide - comprehensive information on resistor technologies

Types of Resistor including Carbon, Film & Composition - educational resource on resistor types

Final thought question: How might the evolution of electronics toward more miniaturized, precision-oriented designs affect the future market share of carbon film versus metal film resistors?

What are the Differences Between Pull up and Pull down Resistors?UTMEL22 October 202534674

What are the Differences Between Pull up and Pull down Resistors?UTMEL22 October 202534674Pull up is to clamp an uncertain signal to a high level with a resistor, and the resistor also acts as a current limiter. In the same way, pull down means to clamp the uncertain signal to a low level through a resistor. To pull up is to input current to the device, and the pull-down is to output the current.

Read More Rheostat Basics: Types, Principle and FunctionsUTMEL25 December 202515921

Rheostat Basics: Types, Principle and FunctionsUTMEL25 December 202515921A rheostat is a device that can adjust the size of the resistance and can be connected to the circuit to adjust the size of the current. A general rheostat is composed of a wire with a larger resistance and a device that can change the contact point to adjust the effective length of the resistance wire. Rheostat can limit the current and protect the circuit, and change the voltage distribution in the circuit.

Read More Basic Introduction to Metal Film ResistorUTMEL28 August 202011494

Basic Introduction to Metal Film ResistorUTMEL28 August 202011494Metal film resistors are a kind of film resistors. Metal film resistors are resistors in which special metals or alloys are used as resistor materials, and the resistor film layer is basically formed on ceramic or glass by vacuum evaporation or sputtering.

Read More Varistor: Definition, Function, Working and TestingUTMEL03 April 202580844

Varistor: Definition, Function, Working and TestingUTMEL03 April 202580844A varistor is a device with a non-linear volt-ampere characteristic. When the voltage applied to the varistor is lower than its threshold value, the current flowing through it is extremely small, which is equivalent to a resistor with infinite resistance, vice versa. The most common varistor is a metal oxide varistor (MOV).

Read More Photoresistor Basics: Types, Principles and ApplicationsUTMEL16 October 202542148

Photoresistor Basics: Types, Principles and ApplicationsUTMEL16 October 202542148The article introduces the photoresistor’s main characteristics and principles including the working principle and structural principle. There are three types of photoresistor: ultraviolet photoresistors, infrared photoresistors, visible light photoresistors. Dimming circuit and light switch are the two applications of the photoresistor.

Read More

Subscribe to Utmel !

![YC158TJR-0710KL]() YC158TJR-0710KL

YC158TJR-0710KLYageo

![LTC5509ESC6#TRMPBF]() LTC5509ESC6#TRMPBF

LTC5509ESC6#TRMPBFLinear Technology/Analog Devices

![HMC611LP4ETR]() HMC611LP4ETR

HMC611LP4ETRAnalog Devices Inc.

![ATSAMR30E18A-MU]() ATSAMR30E18A-MU

ATSAMR30E18A-MUMicrochip Technology

![CC2630F128RGZT]() CC2630F128RGZT

CC2630F128RGZTTexas Instruments

![4310R-101-331]() 4310R-101-331

4310R-101-331Bourns Inc.

![SI4455-B1A-FMR]() SI4455-B1A-FMR

SI4455-B1A-FMRSilicon Labs

![ADA4304-3ACPZ-R7]() ADA4304-3ACPZ-R7

ADA4304-3ACPZ-R7Analog Devices Inc.

![ADRF6850BCPZ-R7]() ADRF6850BCPZ-R7

ADRF6850BCPZ-R7Analog Devices Inc.

![LT5506EUF#PBF]() LT5506EUF#PBF

LT5506EUF#PBFLinear Technology/Analog Devices